Keywords

Computer Science and Digital Science

- A5.5.1. Geometrical modeling

- A5.5.2. Rendering

- A8.3. Geometry, Topology

Other Research Topics and Application Domains

- B5.7. 3D printing

1 Team members, visitors, external collaborators

Research Scientists

- Sylvain Lefebvre [Team leader, Inria, Senior Researcher, HDR]

- Samuel Hornus [Inria, Researcher]

- Jonàs Martínez [Inria, Researcher]

- Camille Schreck [Inria, Starting Faculty Position]

Faculty Member

- Cédric Zanni [Univ de Lorraine, Associate Professor]

PhD Students

- Melike Aydinlilar [Univ de Lorraine]

- Semen Efremov [Inria]

- Jimmy Etienne [CNRS]

- Marco Freire [Univ de Lorraine]

- Thibault Tricard [Univ de Lorraine, until Nov 2021]

Technical Staff

- Jean Baptiste Austruy [Univ de Lorraine, Engineer]

- Adrien Bedel [Inria, Engineer, until Jun 2021]

- Pierre Bedell [Inria, Engineer]

- Pierre Alexandre Hugron [Univ de Lorraine, Engineer, until Nov 2021]

- Yamil Salim Perchy Bocanegra [Inria, Engineer]

- Nathaniel Seyler [Univ de Lorraine, Engineer]

Interns and Apprentices

- Ghilain Bergeron [Inria, from Apr 2021 until Aug 2021]

- Yoann Coudert-Osmont [École Normale Supérieure de Lyon, until Feb 2021]

- Clément Magniez [Univ de Lorraine, from Sep 2021]

- Antoine Raoult [Inria, from Apr 2021 until Jul 2021]

- Yanis Taleb [Inria, from Apr 2021 until Jul 2021]

Administrative Assistants

- Céline Cordier [Inria]

- Virginie Priester [CNRS, until Mar 2021]

2 Overall objectives

Digital fabrication has had a profound impact on most industries. It allows complex products to be modeled in Computer Assisted Design (CAD) software and then sent to Computer-Aided Manufacturing (CAM) devices that physically produce the products. Typical CAM devices are computer-controlled lathes and milling machines that are ubiquitous in mass-production chains, along with injection molding and assembly robots. The design of a new product requires a large pool of expertise consisting of highly skilled engineers and technicians at all stages: design, CAD modeling, fabrication, and assembly chains.

Within CAM technologies, the advent of Additive Manufacturing (AM) (i.e., 3D printing) together with powerful and inexpensive computational resources let us envision a different scenario. In particular, these technologies excel where traditional approaches find their limitations:

- Parts with complex geometry can be fabricated in a single production run, and the cost has no direct relationship with the geometric complexity.

- The cost-per-unit for fabricating an object is constant and significantly lower than producing a small series of objects with traditional means. Though it is not competitive on a mass-production scale where the cost-per-unit decreases as the number of produced units increases.

- The machine setup is largely independent of the object being fabricated, and thus these technologies can be made available through generic 3D printing companies and online print services. Additionally, the machines are significantly easier to operate than traditional fabrication means. This makes them accessible to the general public.

Consequently, it becomes possible to design and produce parts with short development cycles: physical objects are uniquely and efficiently fabricated from digital models. Each object can be personalized for a specific use or customer. The core difficulty in this context lies in modeling parts, and this remains a significant obstacle as functional, and manufacturability constraints have to be enforced. By functional constraint, we refer here to some desired behavior in terms of rigidity, weight, balance, porosity, or other physical properties. This is especially important as AM allows the fabrication of extremely complex shapes, the scales of which vary from a few microns to a few meters. All this pushes AM well beyond traditional means of production and enables the concept of metamaterials; materials where parameterized microstructures change the behavior of a base shape fabricated from a single material.

Exploiting this capability turns the modeling difficulties into acute challenges. Such a quantity of details modeling becomes intractable, and specifying the geometry with standard tools becomes a daunting task, even for experts. Besides, these details have to interact in subtle and specific ways to achieve the final functionality (e.g., flexibility, porosity) while enforcing fabrication constraints. On the process planning side (i.e., the set of computations turning the part into printing instructions), large parts filled with microstructures, porosities, and intricate multi-scale details quickly lead to huge data-sets and numerical issues.

Our overall objective is to develop novel approaches enabling experts and practitioners alike to exploit the advantages of AM fully. We aim to achieve this by developing novel algorithms that automatically synthesize or complete designs with functional details. We consider the full chain, from modeling to geometry processing, to optimize 3D printer instructions.

3 Research program

We focus on the computational aspects of shape modeling and processing for digital fabrication: dealing with shape complexity, revisiting design and customization of existing parts in view of the novel possibilities afforded by AM, and providing a stronger integration between modeling and the capabilities of the target processes.

We tackle the following challenges:

- develop novel shape synthesis and shape completion algorithms that can help users model shapes with features in the scale of microns to meters while following functional, structural, geometric, and fabrication requirements;

- propose methodologies to help expert designers describe shapes and designs that can later be customized and adapted to different use cases;

- develop novel algorithms to adapt and prepare complex designs for fabrication in a given technology, including the possibility to modify aspects of the design while preserving its functionality;

- develop novel techniques to unlock the full potential of fabrication processes, improving their versatility in terms of feasible shapes as well as their capabilities in terms of accuracy and quality of deposition;

- develop novel shape representations, data-structures, visualization, and interaction techniques to support the integration of our approaches into a single, unified software framework that covers the full chain from modeling to printing instructions;

- integrate novel capabilities enabled by advances in additive manufacturing processes and materials in the modeling and processing chains, in particular regarding the use of functional materials (e.g. piezoelectric, conductive, shrinkable).

Our approach is to cast a holistic view on the challenges above by considering modeling and fabrication as a single, unified process. Thus, the modeling techniques we seek to develop will take into account the geometric constraints imposed by the manufacturing processes (minimal thickness, overhang angles, trapped material) and the desired object functionality (rigidity, porosity). To allow for the modeling of complex shapes and adapt the same initial design to different technologies, we propose developing techniques that can automatically synthesize functional details within parts. At the same time, we will explore ways to increase the versatility of the manufacturing processes through algorithms that are capable of exploiting additional degrees of freedom (e.g., curved layering 18), can introduce new capabilities (e.g., material mixing 19) and improve part accuracy (e.g., adaptive slicing 17).

Our research program is organized along with three main research directions. The first one focuses on the automatic synthesis of shapes with intricate multi-scale geometries that conform to additive manufacturing technologies' constraints. The second direction considers geometric and algorithmic techniques for the actual fabrication of the modeled object. We aim to improve further the capabilities of the manufacturing processes with novel deposition strategies. The third direction focuses on computational design algorithms to help model parts with a gradient of properties and help customize existing designs for their reuse.

These three research directions interact strongly and cross-pollinate: e.g., novel possibilities in manufacturing unlock novel possibilities in terms of shapes that can be synthesized. Stronger synthesis methods allow for further customization.

4 Application domains

4.1 Digital Manufacturing

Our work addresses generic challenges related to fabrication and can thus be applied in a wide variety of contexts. Our aim is first and foremost to develop the algorithms that will allow variously industrial sectors to benefit more strongly from the potential of AM. To enable this, we seek collaborations with crucial industry partners developing software and AM systems for a variety of processes and materials that are of interest to specific sectors (e.g., dental, prosthetic, automotive, aerospace).

4.2 Medical Applications

To allow for faster transfer of our techniques and unlock novel applications, we actively seek to develop applications in the medical sector. In particular, we are involved in a project around the design of orthoses, which explores how our research on elasticity control through microstructure geometries can be specifically applied to the medical sector.

5 Highlights of the year

This year we made advances in trajectory optimization for additive manufacturing, with in particular the works on cyclic deposition 15 and oriented deposition 14, addressing important challenges in Additive Manufacturing. We are also reaching new milestones in terms of displaying large amounts of complex geometries, from deposition trajectories to intricate small-scale geometries 10.

We have achieved intriguing results regarding the modeling of micro-structures, in particular regarding the modeling of stochastic structures with negative Poisson's ratio 13, and the modeling of near-regular structures 12 that can progressively vary in their small scale geometries while maintaining specific symmetries.

6 New software and platforms

6.1 New software

6.1.1 IceSL

-

Keyword:

Additive manufacturing

-

Scientific Description:

IceSL is the software developed within MFX, that serves as a research platform, a showcase of our research results, a test bed for comparisons and a vector of collaborations with both academic and industry partners. The software is freely available both as a desktop (Windows/Linux) and as an online version.

-

Functional Description:

IceSL allows users to model complex shapes through CSG boolean operations. Objects can be directly prepared and sent to a 3D printer for fabrication, without the need to compute an intermediate 3D mesh.

-

News of the Year:

While IceSL has historically targeted filament printers, the core technology applies to a wide range of processes. A complete rework of the slicing pipeline for image-based printing technologies was done and properly tested. IceSL now supports resin printers with special attention to the widely available printers supporting the "PHOTON" format.

Multiple upgrades were made to its plugin system that are significant in how they further exploit the configurability and modularity of IceSL's slicing and printing pipeline. We single out two, 1) the added option to post-process the produced slices to add/remove/modify printing segments where essential steps in printing such as extruder positioning are offloaded from the plugin and automatically calculated by IceSL, and 2) the ability to fallback to native IceSL infilling of geometry whenever a plugin only manages/decides to fill a subpart of the volume.

As usual, several updates to the software addressing printing quality (especially small-scale), performance, UI design and configurability were done in the span of the year. Cumulative downloads of the software are around 145k with an uptick of 55k compared to last year (due to more incremental version releases). The web version saw an increase of 50% of use (22K on 2021 vis-à-vis 15K on 2020) with an average of a 100 uses per day (compared to 75 in last year).

- URL:

-

Authors:

Sylvain Lefebvre, Frédéric Claux, Jonas Martinez Bayona, Jean Hergel, Jérémie Dumas, Samuel Hornus, Yamil Salim Perchy Bocanegra, Cedric Zanni, Pierre Bedell, Jimmy Etienne, Haichuan Song, Thibault Tricard, Pierre-Alexandre Hugron

-

Contact:

Sylvain Lefebvre

6.1.2 IceSL WebPrinter

-

Name:

IceSL Web3DPrinter

-

Keyword:

3D printing

-

Functional Description:

In Web3DPrinter, a user can input (either by loading it or by copy-pasting it) a Gcode destined to any 3D printer. The tool will then parse the Gcode and produce a visual simulation of it. The loaded Gcode can also be browsed and modified in the attached text editor, allowing to see in real time the impact of such modification. Following the last feature, the tool can provide an easy-to-use setup for educational purposes.

-

Release Contributions:

-

-

News of the Year:

In 2021 we continued to develop Web3DPrinter and to use it as a teaching tool, allowing students to test GCode produced during class in the browser.

-

Authors:

Pierre Bedell, Yamil Salim Perchy Bocanegra, Sylvain Lefebvre

-

Contact:

Sylvain Lefebvre

6.1.3 Silice

-

Name:

Silice

-

Keywords:

FPGA, Programming

-

Functional Description:

Silice makes it possible to write algorithms for FPGAs in the same way we write them for processors: defining sequences of operations, subroutines that can be called, and using control flow statements such as while and break. At the same time, Silice lets you fully exploit the parallelism and niceties of FPGA architectures, describing operations and algorithms that run in parallel and are always active, as well as pipelines. Silice remains close to the hardware: nothing gets obfuscated away. When writing an algorithm you are in control of what happens at which clock cycle, with predictable rules for flow control. Clock domains are exposed. In fact, Silice compiles to and inter-operates with Verilog: you can directly instantiate and bind with existing modules.

-

Release Contributions:

2021 version.

-

News of the Year:

Sylvain Lefebvre is continuing work on Silice, exploring the use of FPGA architectures for high performance Graphics and Geometry processing. In 2021, Silice was featured in two invited presentations at the South Indian SDR Users Group (https://www.youtube.com/channel/UCy04XwXPMDVUucWYYvwg-Yg). Three interns worked on Silice: Ghilain Bergeron on formal verification, Yanis Taleb and Antoine Raoult on a specialized debugger (early version on https://github.com/shin0bi-y/silice-debugger).

- URL:

-

Author:

Sylvain Lefebvre

-

Contact:

Sylvain Lefebvre

6.2 New platforms

Participants: Pierre Bedell, Pierre-Alexandre Hugron.

We continued our active participation within the Creativ'Lab, a common experimental platform funded by Inria, Loria, CNRS and Région Grand Est.

A second room was setup for resin printers and our 3D printing robot equipment. We acquired and installed a new FormLabs Form 3L printer. The room also hosts 3D printers of the LARSEN team, creating a collaborative space around resin printing and between both teams in general.

7 New results

7.1 3D periodic cellular materials with tailored symmetry and implicit grading

Participants: Semyon Efremov, Jonàs Martínez, Sylvain Lefebvre.

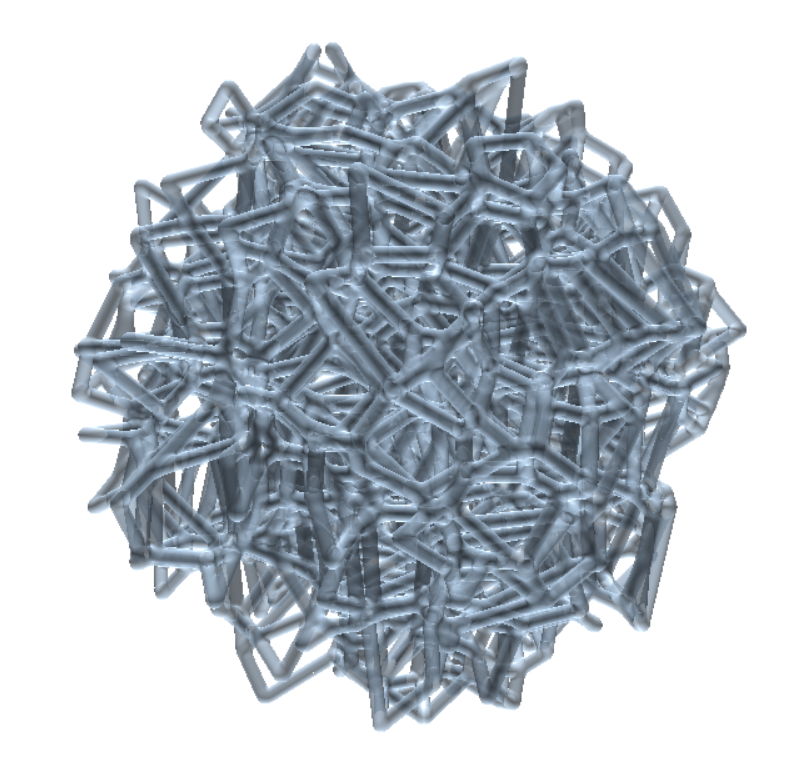

3D periodic cellular materials are an essential ingredient in the manufacture of advanced functional parts. They allow triggering various elastic responses within a part by structuring its internal volume at a small scale. Ideally, a method to model cellular materials would allow for a wide gamut of elastic responses and geometries that could be freely chosen within the part volume. In this work, we study a novel type of 3D periodic cellular materials that emerge from a growth process in a lattice. The growth is parameterized by a 3D star-shaped set at each lattice point, defining the geometry that will appear around it. Individual tiles may be computed and used in a periodic lattice, or a global structure may be produced under spatial gradations, changing the parametric star-shaped set at each lattice location. Beyond free spatial gradation, an important advantage of our approach is that elastic symmetries can easily be enforced. We show how shared symmetries between the lattice and the star-shaped set directly translate into symmetries of the periodic structures' elastic response. Thus, our approach enables restricting the symmetry of the elastic responses – monoclinic, orthorhombic, trigonal, and so on – while freely exploring a wide space of possible geometries and topologies (see Figure 2).

This work has been presented at the SIAM Conference on Geometric and Physical Modeling and published at the journal Computer-Aided Design 12.

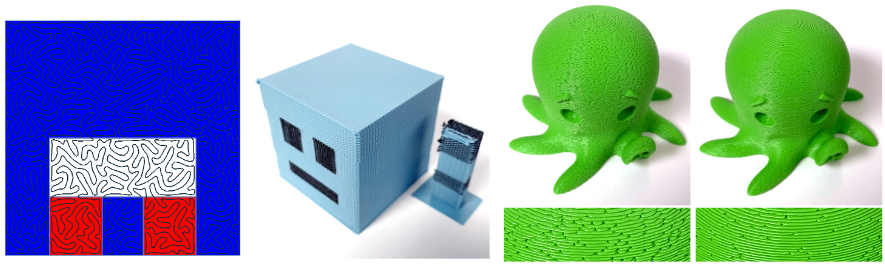

7.2 Closed space-filling curves with controlled orientation for 3D printing

Participants: Adrien Bedel, Yoann Coudert-Osmont, Jonàs Martínez, Rahnuma Islam Nishat, Sue Whitesides, Sylvain Lefebvre.

We explore the optimization of closed space-filling curves under orientation objectives. By solidifying material along the closed curve, solid layers of 3D prints can be manufactured in a single continuous extrusion motion. The control over orientation enables the deposition to align with specific directions in different areas, or to produce a locally uniform distribution of orientations, patterning the solidified volume in a precisely controlled manner. Our optimization framework proceeds in two steps. First, we cast a combinatorial problem, optimizing for Hamiltonian cycles within a specially constructed graph. We rely on a stochastic optimization process based on local operators that modify a cycle while preserving its Hamiltonian property. Second, we use the result to initialize a geometric optimizer that improves the smoothness and uniform coverage of the cycle while further optimizing for alignment and orientation objectives.

This work was published at as a technical report 15 and is under review (conditionally accepted for publication).

Optimization of cyclic deposition trajectories.

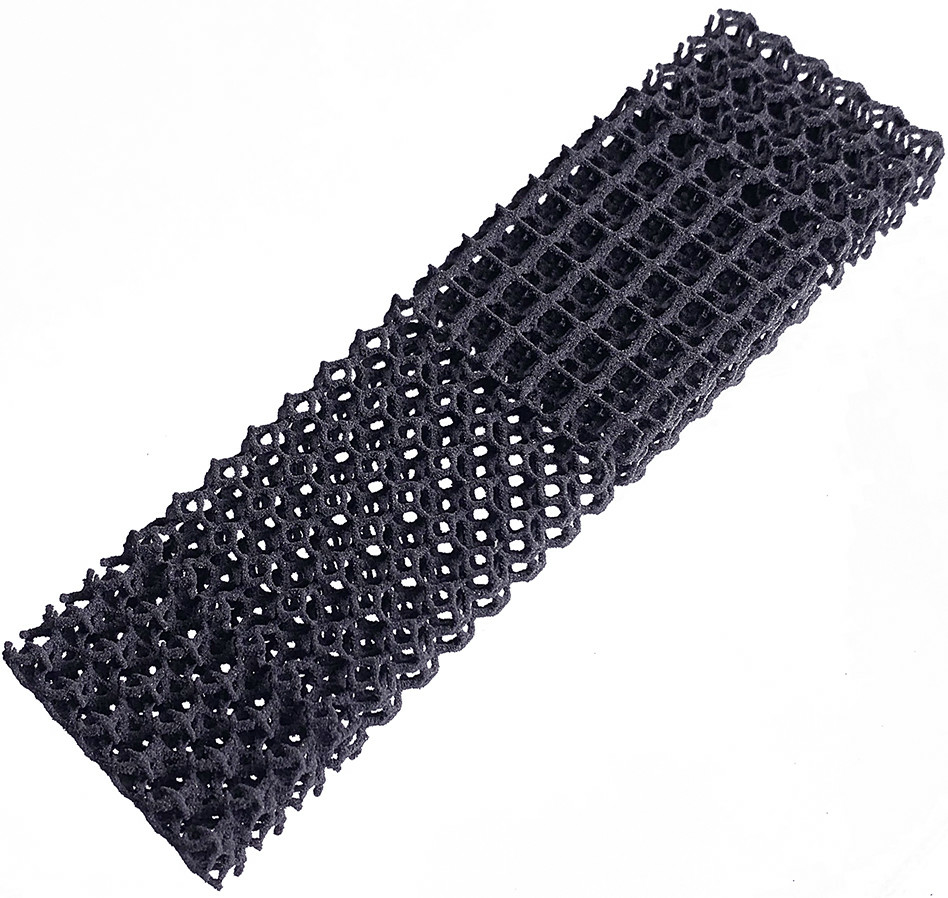

7.3 Random auxetic porous materials from parametric growth processes

Participants: Jonàs Martínez.

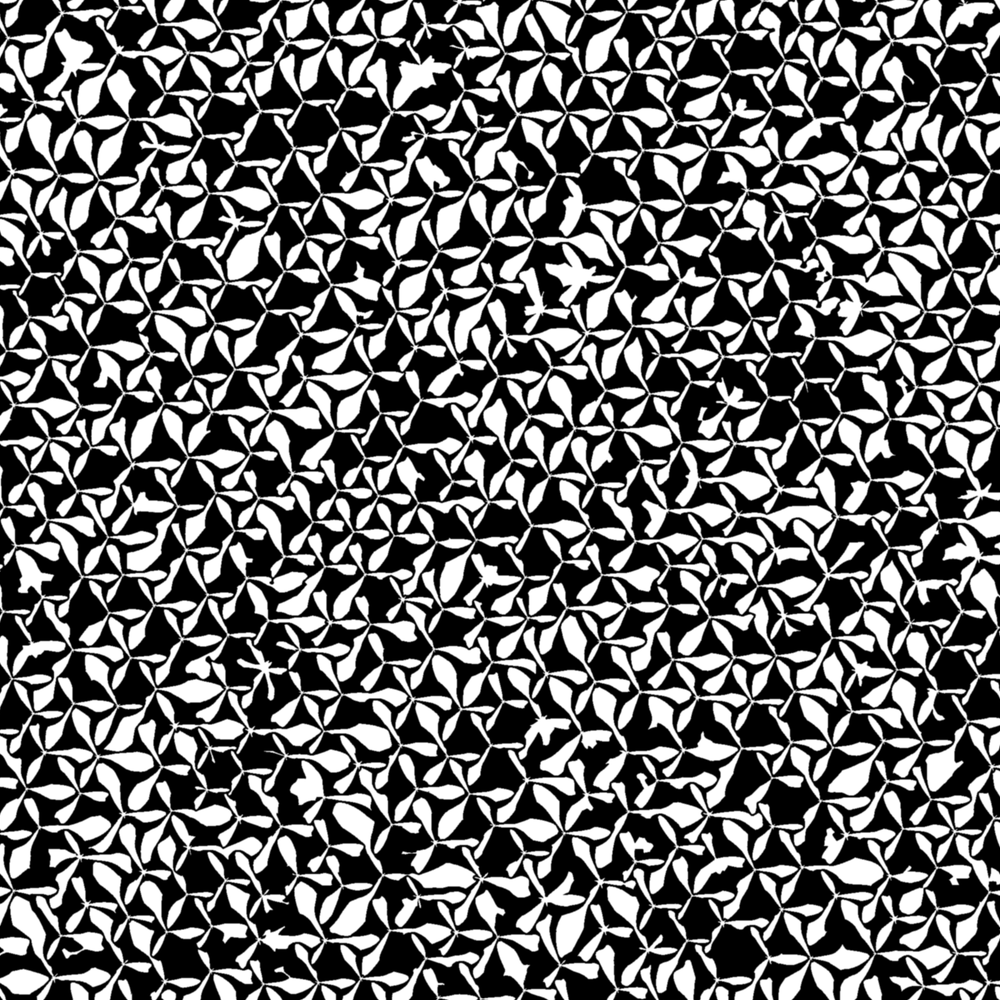

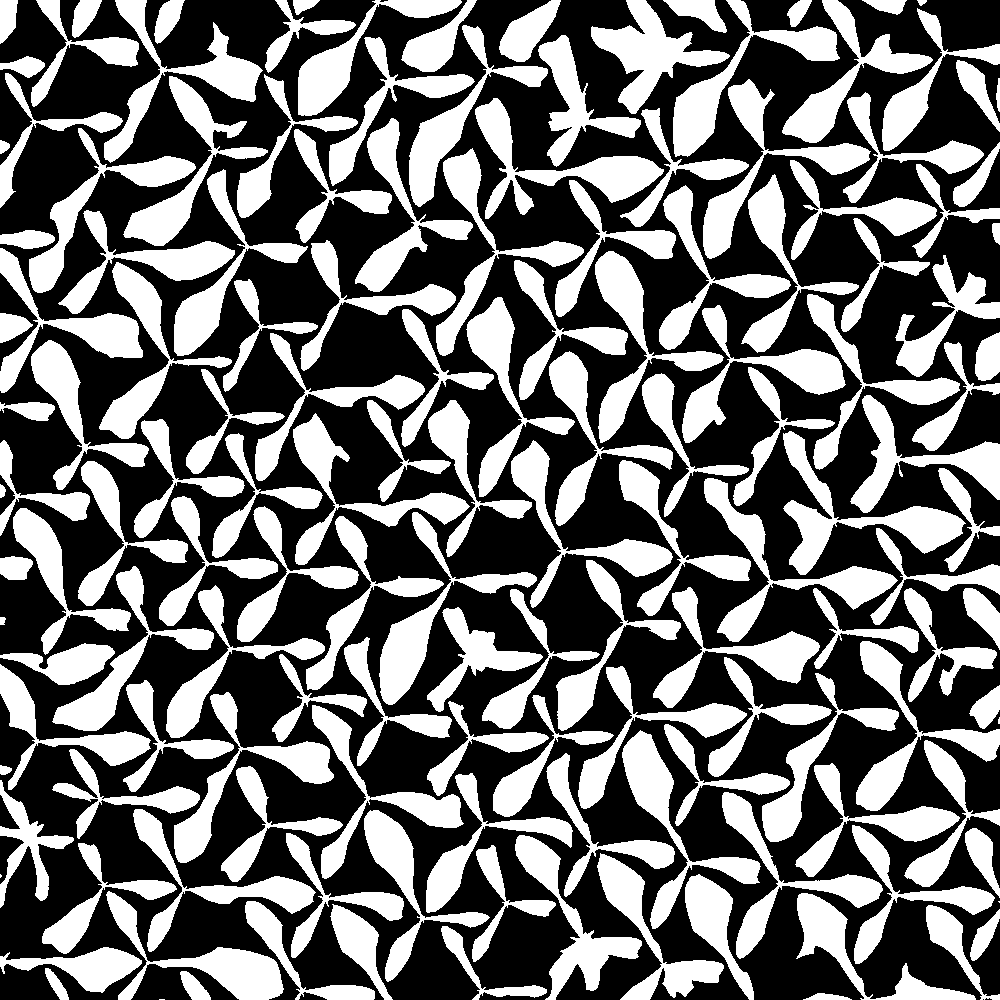

Recent works dealing with the generation of two-dimensional random auxetic materials consider a random network whose parameters are iteratively optimized in order to minimize the Poisson's ratio. These works eventually become computationally inefficient as the size of the network increases. Instead, we propose to precompute the parameters of a novel type of growth process. The growth process involves randomly placed non-overlapping cells that grow according to a parameterized growth law. Remarkably, the process of growth intrinsically entails the formation of an auxetic material that can be computed very efficiently. Our approach enables the computation of large-scale random auxetic materials in commodity computers (see Figure 4).

The results of this research were published in the journal Computer-Aided Design 13. Open-source code and data are available here. This work has received the recognition of the Graphics Replicability Stamp Initiative.

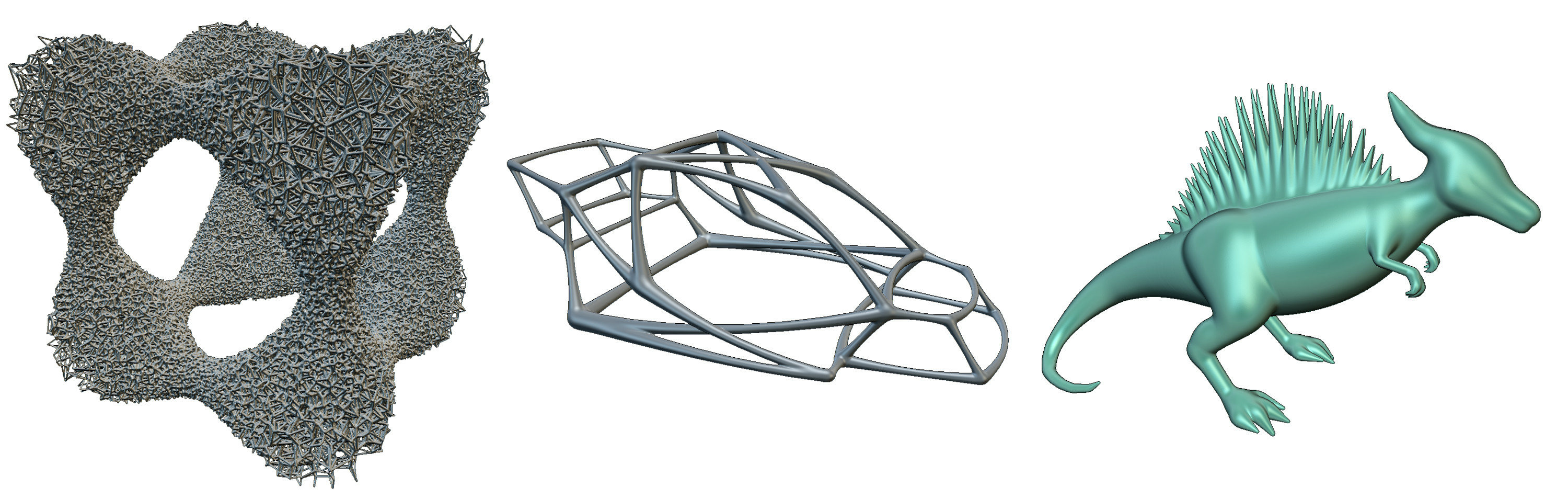

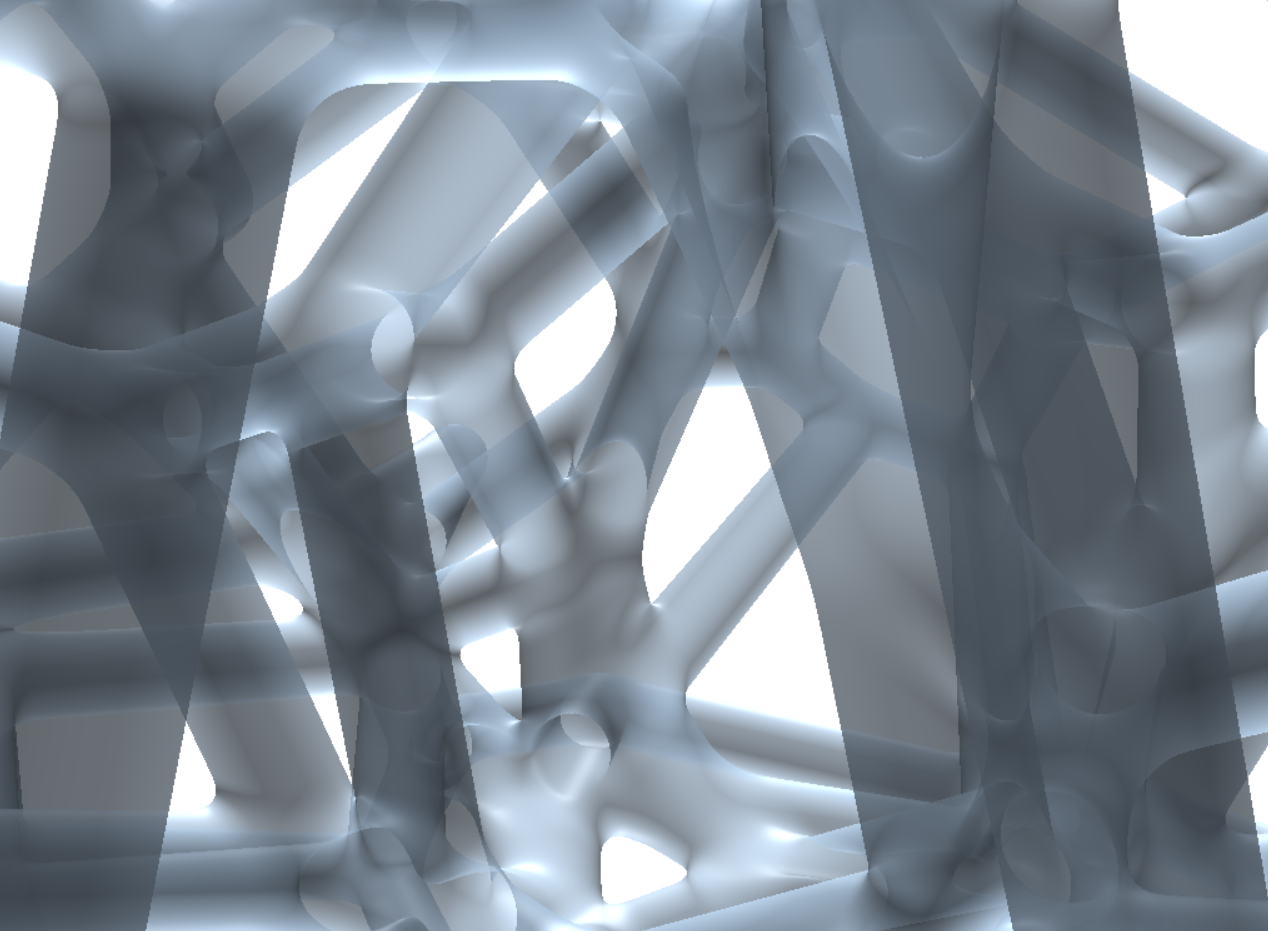

7.4 Processing skeleton-based implicit surfaces

Participants: Melike Aydinlilar, Nathaniel Seyler, Cédric Zanni.

Scale-invariant integral surfaces, which are implicit representations of surfaces, provide a way to define smooth surfaces from skeletons with prescribed radii defined at their vertices. They can be used to represent a large range of shapes, from procedural foam structures to truss structures and artistic shapes (see Figure 5). We introduce a new rendering pipeline allowing us to visualize such surfaces in real-time. The proposed method relies on combining a new field normalization, a ray segmentation based on the distance to primitives, and iterative quadratic approximations. Our GPU implementation uses a dynamic data-structure to provide constant-time access to primitive during ray processing.

This work has been published in the journal Computer Graphic Forum 10. The implementation is done as an IceSL plugin (currently private).

We also investigated various extensions of the method to both the transparent rendering and slicing of implicit surfaces (both can be done relying on the same base algorithm). We first studied a practical algorithm based on tight field value interval ranges. When high precision is required, the method performs better than state of the art slicing methods. This method has been submitted as a short paper to Eurographics 2022. The other approach studied relies on precise local quadratic bounds of the field values in order to achieve robust root isolation along rays. The methodology allows for both iterative ray processing as in segment-tracing and recursive ray processing as in revised affine arithmetics. This work is not yet published.

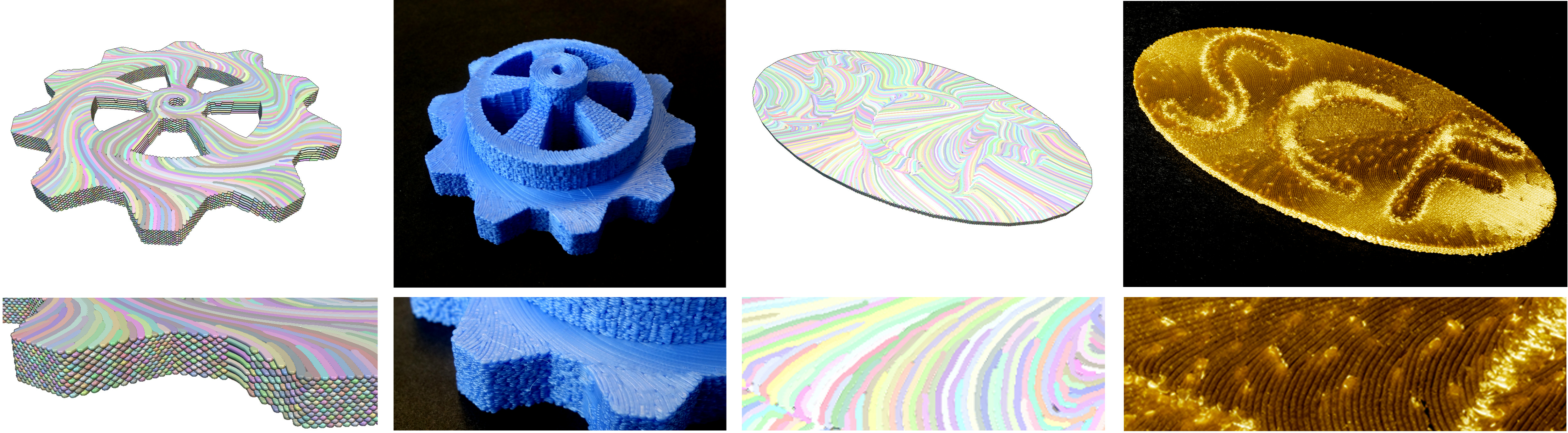

7.5 Staggered orientable infills for additive manufacturing

Participants: Thibault Tricard, Jimmy Etienne, Cédric Zanni, Sylvain Lefebvre.

Additive manufacturing is typically conducted in a layer-by-layer fashion. A key step of the process is to define, within each planar layer, the trajectories along which material is deposited to form the final shape. The direction of these trajectories triggers an anisotropy in the fabricated parts, which directly affects their properties, from their mechanical behavior to their appearance. Controlling this anisotropy paves the way to novel applications, from stronger parts to controlled deformations and surface patterning. This work introduces a method to generate trajectories that precisely follow an input direction field while simultaneously avoiding intra- and inter-layer defects. Our method results in spatially coherent trajectories - all follow the specified direction field throughout the layers - while providing precise control over their inter-layer arrangement. This allows us to generate a staggered layout of trajectories across layers, preventing unavoidable tiny gaps from forming tunnel-shaped voids throughout a part volume. Our approach is simple, robust, easy to implement, and scales linearly with the input volume. It builds upon recent results in procedural generation of oscillating patterns, generating a signal in the 3D domain that oscillates with a frequency matching the deposition beads width while following the input direction field. Trajectories are extracted with a process akin to a marching square.

This work has been presented at ACM Symposium on Computational Fabrication 14.

Illustrations of applications of staggered infills for structural and visual effects.

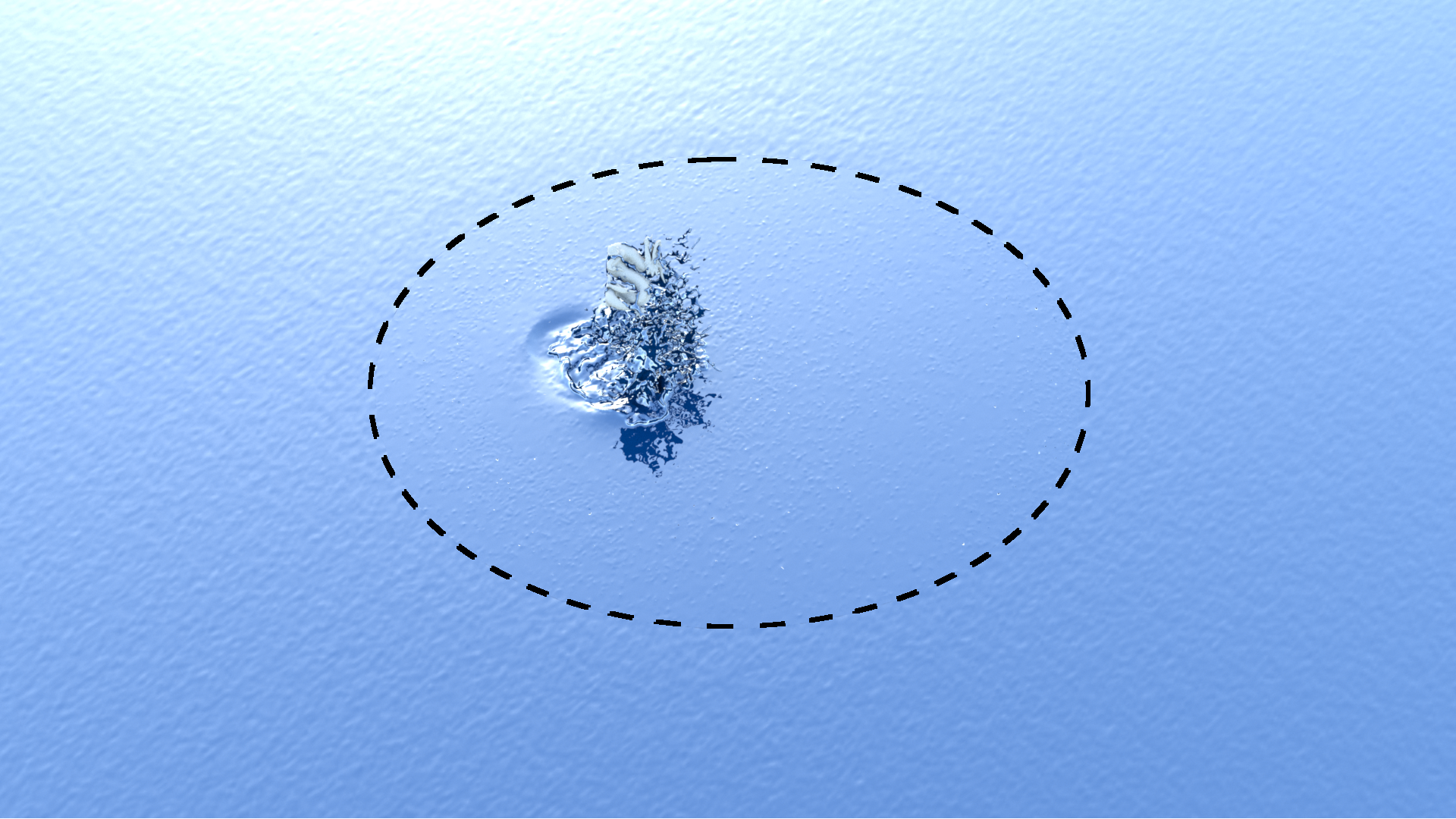

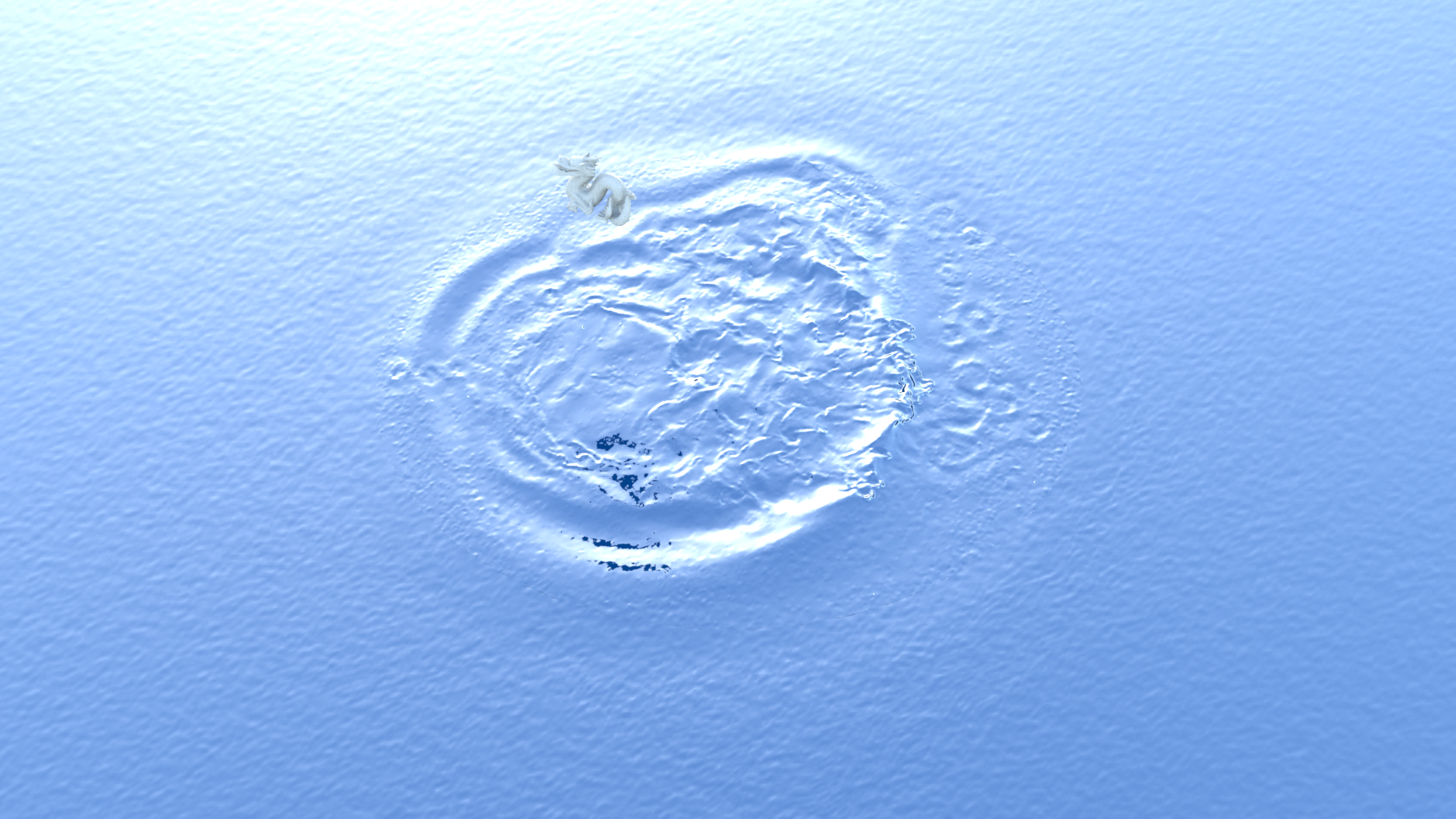

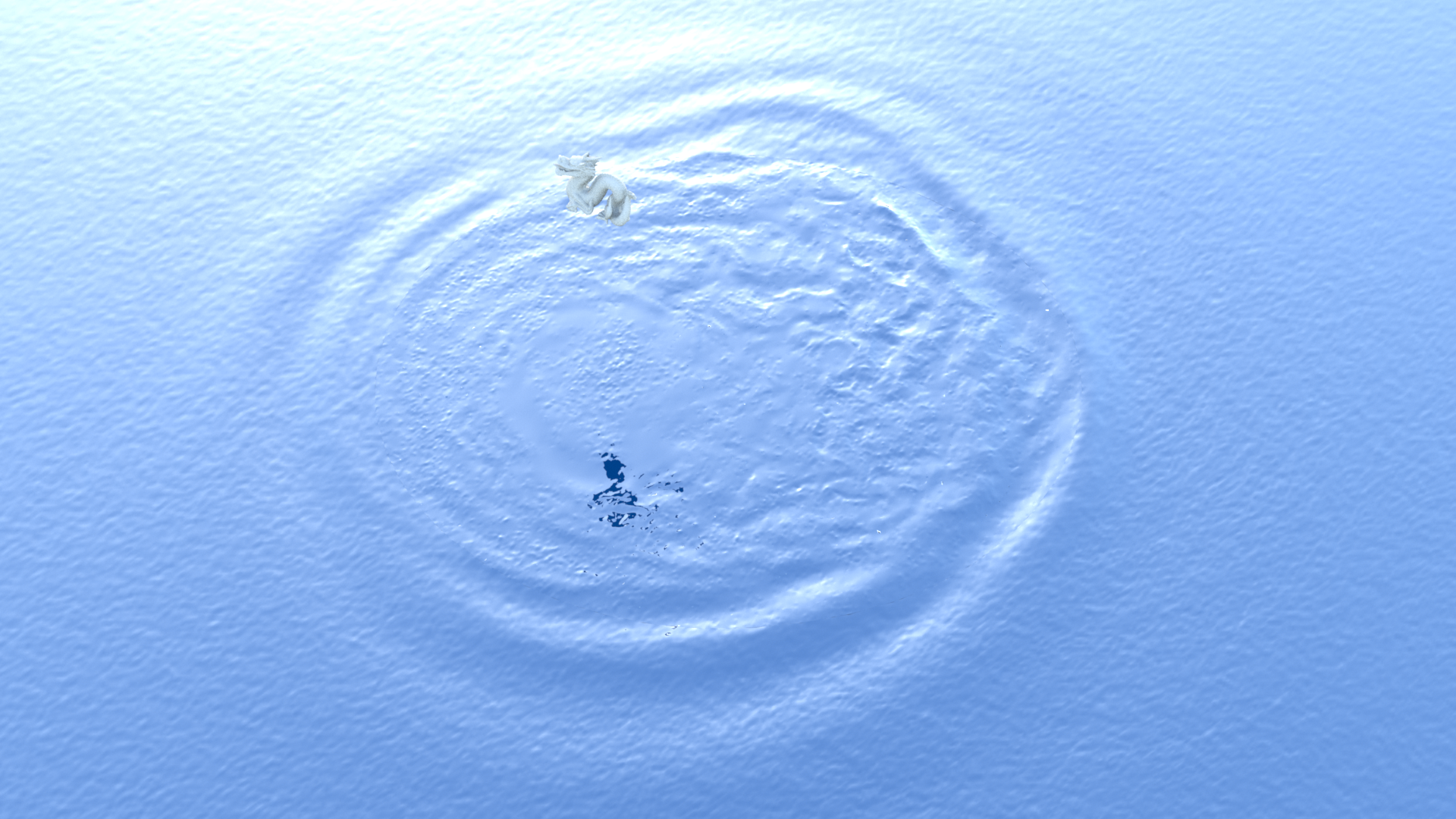

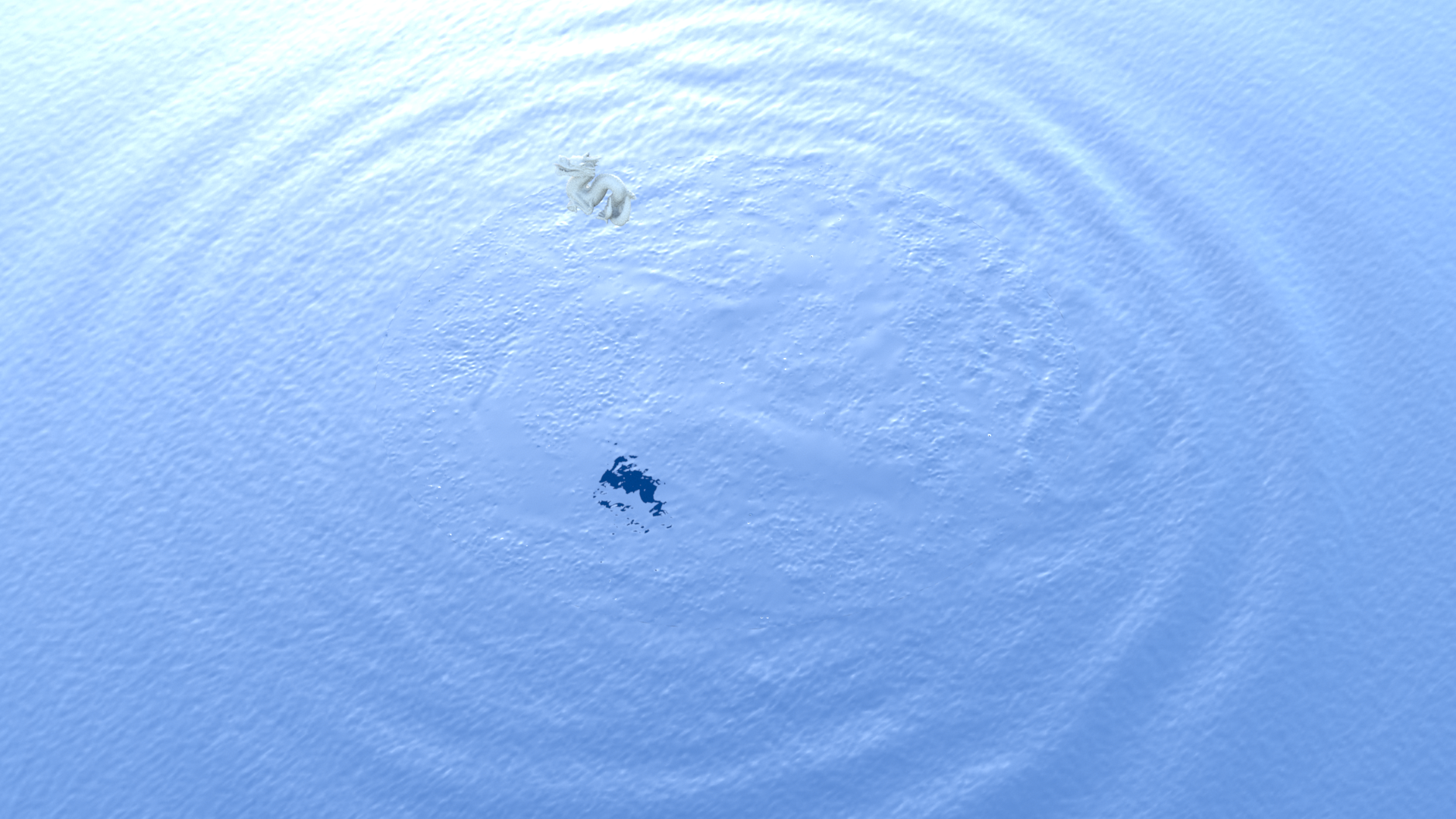

7.6 Coupling 3D Liquid Simulation with 2D Wave Propagation for Large Scale Water Surface Animation Using the Equivalent Sources Method

Participants: Camille Schreck, Chris Wojtan.

Progress in fluid simulation has made water scenes in animated movies and games increasingly realistic. However, the simulation of very large scenes with convincing visual details is still extremely expensive and challenging.

We propose a method for simulating liquids in large bodies of water by coupling together a water surface wave simulator with a 3D Navier-Stokes simulator. The surface wave simulation uses the equivalent sources method (ESM) to efficiently animate large bodies of water with precisely controllable wave propagation behavior. The 3D liquid simulator animates complex non-linear fluid behaviors like splashes and breaking waves using off-the-shelf simulators using FLIP or the level set method with semi-Lagrangian advection.

We combine the two approaches by using the 3D solver to animate localized non-linear behaviors, and the 2D wave solver to animate larger regions with linear surface physics. We use the surface motion from the 3D solver as boundary conditions for 2D surface wave simulator, and we use the velocity and surface heights from the 2D surface wave simulator as boundary conditions for the 3D fluid simulation.

We also introduce a novel technique for removing visual artifacts caused by numerical errors in 3D fluid solvers: we use experimental data to estimate the artificial dispersion caused by the 3D solver and we then carefully tune the wave speeds of the 2D solver to match it, effectively eliminating any differences in wave behavior across the boundary. To the best of our knowledge, this is the first time such a empirically driven error compensation approach has been used to remove coupling errors from a physics simulator.

Our coupled simulation approach leverages the strengths of each simulation technique, animating large environments with seamless transitions between 2D and 3D physics.

This work has been submitted to Eurographics 2022.

8 Bilateral contracts and grants with industry

8.1 Bilateral contracts with industry

Partnership with AddUp

- Company: AddUp.

- Duration: Started in 2019.

- Participants: Sylvain Lefebvre.

- Abstract: AddUp (https://www.addupsolutions.com/) is a French manufacturer of metal 3D printers for high-end industrial applications. We announced during FormNext 2019 (November) a partnership towards the creation of new software technologies. This partnership continued to develop in 2021 with several new advances.

9 Partnerships and cooperations

9.1 National initiatives

9.1.1 ANR

Project MuFFin

- Acronym: MuFFin.

- Title: Procedural Stochastic Microstructures for Functional Fabrication.

- Duration: 2018-2021.

- Funding: ANR JCJC.

- Coordinator: Jonàs Martínez.

- Participants: Jonàs Martínez, Sylvain Lefebvre, Samuel Hornus, Semyon Efremov.

-

Abstract:

MuFFin aims at contributing a unified pipeline for the efficient and scalable synthesis, visualization, and modeling of additively manufactured microstructures with tailored macroscopic physical behavior. In an interdisciplinary effort, MuFFin will blend computer and material science perspectives to deliver an integrated approach that is both computationally and physically sound.

This year, two research projects emerging from the MuFFin project have resulted in international publications: the work of 3D periodic materials with tailored symmetry 12 and the work of 2D random auxetic materials 13.

Project IMPRIMA

- Acronym: IMPRIMA.

- Title: Implicit modeling for additive manufacturing.

- Duration: 2019-2023.

- Funding: ANR JCJC.

- Coordinator: Cédric Zanni.

- Participants: Cédric Zanni, Sylvain Lefebvre, Melike Aydinlilar, Nathaniel Seyler.

-

Abstract:

Project IMPRIMA seeks to explore novel implicit representations to provide a unified approach for the modeling and slicing of both macro geometry, microstructures, and gradient of material. Additionally, this research aims to complete tight integration of both standard boundary representations and novel implicit volume representations, allowing the best choice of representation for different parts of a design.

Our latest results on the visualization of scale-invariant integral surfaces (SCALIS), a surface representation suited for the description of both micro and macro geometry, has lead to a publication on interactive rendering 10, a short paper submission to Eurographics on transparent rendering and slicing. Our work on skeleton rendering has also been used for printing path rendering.

9.2 Inria initiatives

9.2.1 ADT (Action de Développement Technologique)

Project IceSL future

- Acronym: IceSL future.

- Title: IceSL future.

- Duration: 2021-2023.

- Funding: Inria.

- Coordinator: Sylvain Lefebvre, Cédric Zanni.

- Participants: Sylvain Lefebvre, Cédric Zanni, Salim Perchy, Nathaniel Seyler, Thibault Tricard.

-

Abstract:

We have started to work on the ADT (Action de Développement Technologique) project IceSL-future, which is a follow up of previous ADT project IceXXL.

This project aims at facilitating transfer activity and technological evolution of the software IceSL (notably the integration of our latest research) by doing a large-scale refactoring of the IceSL code base. This answers the following needs: some of our current works are difficult to integrate in the existing architecture, the entry cost (codewise) is high for newcomers (PhD students, engineer,...), parts of the code base cannot be easily reused in new projects, the code base becomes increasingly difficult to maintain, especially during period where the team does not have access to an engineer.

The objective is therefore to provide a geometric and trajectory kernel targeted at additive manufacturing. This kernel should provide an ultra modular architecture and be extensible dynamically. The current code base will be decomposed in technological bricks consisting of libraries/modules with clear/documented API at boundaries. Bricks can then be composed based on user/partner needs.

The first phase of the project is underway and consists in the implementation of a vertical slice of a command line slicing application, with a focus on interfaces between different slicing steps, solid representations and printing parameters management.

In parallel, we have also initiated a vertical slice of a rendering application to study the possibility of using the Vulkan rendering API.

9.2.2 Inria Challenge

Project DORNELL

- Acronym: DORNELL.

- Title: IceSL future.

- Duration: 2020-2024.

- Funding: Inria.

- Coordinator: Marie Babel and Claudio Pacchierotti.

- Participants: Sylvain Lefebvre, Pierre-Alexandre Hugron, Salim Perchy, Marco Freire.

-

Abstract:

While technology helps people to compensate for a broad set of mobility impairments, visual perception and/or cognitive deficiencies still significantly affect their ability to move safely and easily. DORNELL proposes an innovative multisensory, multimodal, smart haptic handle that can be easily plugged onto a wide range of mobility aids. Specifically fabricated to fit the needs of a person, it provides a wide set of ungrounded tactile sensations in a portable and plug-and-play format – bringing haptics in assistive technologies all at once. The project addresses important scientific and technological challenges, including the study of multisensory perception, the use of new materials for multimodal haptic feedback, and the development of a haptic rendering API to adapt the feedback to different assistive scenarios and user’s wishes. DORNELL is co-designed with users and therapists, driving our development by their expectations and needs.

10 Dissemination

10.1 Promoting scientific activities

10.1.1 Conferences

Member of the conference program committees

- Jonàs Martínez was an associate editor of 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems.

- Cédric Zanni was on the international program committee of Shape Modeling International (SMI 2021).

- Camille Schreck was on the international program committee of Shape Modeling International (SMI 2021).

- Sylvain Lefebvre was on the SIGGRAPH Asia 2021 program committee and the EUROGRAPHICS 2021 program committee.

Reviewer

- Jonàs Martínez was reviewer for SIGGRAPH 2021.

- Cédric Zanni was on the best paper committee of Les journées Françaises de l'Informatique Graphique (JFig 2021).

- Camille Schreck was on the best paper committee of Les journées Françaises de l'Informatique Graphique (JFig 2021).

- Camille Schreck was reviewer for SIGGRAPH 2021 and SIGGRAPH Asia 2021.

- Samuel Hornus was reviewer for GRAPP 2021 and 2022.

- Sylvain Lefebvre was reviewer for SIGGRAPH 2021.

10.1.2 Journal

Reviewer - reviewing activities

- Jonàs Martínez was a reviewer for ACM Transactions on Graphics, Computer-Aided Design, and Computer Aided Geometric Design.

- Samuel Hornus was reviewer for ACM Transactions on Graphics.

- Sylvain Lefebvre was reviewer for IEEE Transactions on Visualization and Computer Graphics.

10.1.3 Invited talks

Jonàs Martínez gave invited talks at:

- JFIG 2021: “Parametric Growth Processes for Metamaterial Design”. The slides of the talk are available here.

- Workshop GDR MePhy: “Stochastic metamaterials for Additive Manufacturing”.

- WAM 2021: “Additive manufacturing of small-scale geometry with controllable elasticity”.

- Computational Fabrication Seminar: “Metamaterials for Additive Manufacturing”. Online presentation available here.

Sylvain Lefebvre gave invited talks at:

- The 2021 IDEA league summer school on Computational Design for Additive Manufacturing, see here.

- The Dagstuhl seminar "Geometric Modeling: Interoperability and New Challenges", held November 21 to 26, 2021, see here.

- The South Indian SDR User Group, two talks in 2021 available here: "Silice: A language to hardcode algorithms in FPGAs", "The Ice-V dual, a small dual core RISCV RV32I CPU".

10.1.4 Research administration

- Sylvain Lefebvre is animating the local “Comité du Développement Technologique” since september 2020.

- Since 2020, Sylvain Lefebvre is co-organizing the 'TutoTechno' with Bertrand Wallrich and Monique Teillaud, a series of tutorial events on emerging technologies within the Inria Nancy Grand-Est center.

- Sylvain Lefebvre is a member of the "Bureau du Comité des Projets" of Inria Nancy.

10.2 Teaching - Supervision - Juries

10.2.1 Teaching

- Master: Jonàs Martínez, Introduction to data parallelism, 18h ETD, Université de Lorraine, France.

- Master: Jonàs Martínez, Advanced machine architectures (GPU), 27h ETD, Télécom Nancy, France.

- Master: Cédric Zanni, Software Engineering, 31.5h ETD, M1, École des Mines de Nancy, France.

- Master: Cédric Zanni, Programming Language, 14h ETD, M1, École des Mines de Nancy, France.

- Master: Cédric Zanni, Introduction to C/C++, 27h ETD, M1, École des Mines de Nancy, France.

- Master: Cédric Zanni, Techniques for video game programming, 30h ETD, M1, École des Mines de Nancy, France.

- Master: Cédric Zanni, ARTEM Game Lab, 16h ETD, M1, École des Mines de Nancy, France.

- Master: Sylvain Lefebvre, Additive manufacturing for soft robotics, 6h ETD, École Polytechnique, Saclay, France.

- Master: Sylvain Lefebvre, Introduction to parallel programming, 9h ETD, ENSG Nancy, France.

- Master: Sylvain Lefebvre, Introduction to additive manufacturing, 9h ETD, ENSEM Nancy, France.

- License : Cédric Zanni, Introduction to Computer Science, 12h ETD, École des Mines de Nancy, France.

- License : Samuel Hornus, Mathematics for Computer Science, 32h ETD, Télécom Nancy, France. (responsible of class series for 2019-2020.)

- Master: Thibault Tricard, ARTEM Game Lab, 24h ETD, M1, École des Mines de Nancy, France.

- Master: Thibault Tricard, Introduction to data parallelism, 12h ETD, Université de Lorraine, France.

- IUT: Jimmy Etienne, Introduction to programming, 56h ETD, IUT Charlemagne (Nancy), France.

- IUT: Jimmy Etienne, Second year project supervision, 8h, IUT Charlemagne (Nancy), France.

- Master: Camille Schreck, Introduction to 3D Graphics, 24h ETD, Telecom Nancy, France.

- Master: Camille Schreck, Introduction to additive manufacturing, 6h ETD, ENSEM Nancy, France.

- Master: Camille Schreck, 3D Graphics and Parallelism, 12h ETD, ENSG Nancy, France.

10.2.2 Supervision

- PhD in progress: Semyon Efremov, procedural microstructures for additive manufacturing, started October 2018, advisors: Jonàs Martínez, Sylvain Lefebvre

- PhD in progress : Jimmy Etienne, Curved slicing for additive manufacturing, started September 2018, advisors: Sylvain Lefebvre, Cédric Zanni

- PhD in progress : Melike Aydinlilar, Implicit modeling for additive manufacturing, started November 2019, advisors: Cédric Zanni, Sylvain Lefebvre.

- PhD in progress : Thibault Tricard, Procedural synthesis of structured patterns, started October 2018, advisors: Sylvain Lefebvre, Dider Rouxel (IJL).

- PhD in progress : Marco Freire, Layout problems in Computer Graphics and beyond, started October 2020, advisor: Sylvain Lefebvre.

10.2.3 Juries

- Sylvain Lefebvre was "rapporteur" for the PhD defense of Thomas Buffet (Sorbonne Université), held on January 13, 2021.

- Sylvain Lefebvre was "rapporteur" for the PhD defense of Nicolas Lutz (Université de Strasbourg), held on July 1st, 2021.

- Sylvain Lefebvre was external reviewer for the PhD thesis of Thomas Alderighi (University of Pisa).

- Sylvain Lefebvre was external reviewer for the mid-term PhD juries of Eli Michel (Télécom Paris), Maud Lastic (École Polytechnique), Emmanuel Rodriguez (Inria).

10.3 Popularization

Sylvain Lefebvre gave a talk on Computer Graphics and FPGAs, The Doom-chip "On Ice": designing hardware for a 1993 retro-classic

Beyond the team website, we maintain an online activity towards a general audience, in particular on the IceSL forum (200 members) and IceSL twitter account (@iceslapp, 580 followers).

11 Scientific production

11.1 Major publications

- 1 articleOptimal discrete slicing.ACM Transactions on Graphics361February 2017, 1 - 16

- 2 articleBridging the Gap: Automated Steady Scaffoldings for 3D Printing.ACM Transactions on Graphics334July 2014, 98:1 - 98:10

- 3 articleVariable-width contouring for additive manufacturing.ACM Transactions on Graphics394 (Proc. SIGGRAPH)July 2020

- 4 articleBy-example synthesis of structurally sound patterns.ACM Transactions on Graphics2015

- 5 articleProcedural Voronoi Foams for Additive Manufacturing.ACM Transactions on Graphics352016, 1 - 12

- 6 articleStructure and appearance optimization for controllable shape design.ACM Transactions on Graphics346November 2015, 12

- 7 articlePolyhedral Voronoi diagrams for additive manufacturing.ACM Transactions on Graphics374August 2018, 15

- 8 articleOrthotropic k-nearest foams for additive manufacturing.ACM Transactions on Graphics364July 2017, 121:1--121:12

- 9 articleFreely orientable microstructures for designing deformable 3D prints.ACM Transactions on GraphicsDecember 2020

11.2 Publications of the year

International journals

International peer-reviewed conferences

Reports & preprints

11.3 Cited publications

- 17 articleOptimal discrete slicing.ACM Transactions on Graphics361February 2017, 1 - 16

- 18 articleSupport-free volume printing by multi-axis motion.ACM Transactions on Graphics374July 2018, 1 - 14

- 19 unpublishedColored fused filament fabrication.December 2017, working paper or preprint