Section: Partnerships and Cooperations

National Initiatives

ANR

“Young Researcher” VIDA (2017-2021)

LP2N-CNRS-IOGS Inria

Leader R. Pacanowski (LP2N-CNRS-IOGS)

Participant P. Barla (Inria)

Context.

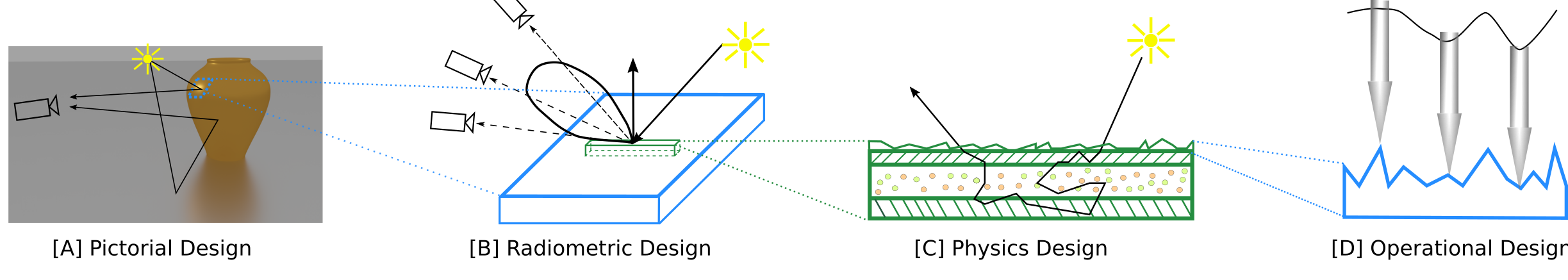

Since the beginning of the industrial era, prototyping has been an important stage for manufacturers as a preliminary step before mass production. With the rise of Computer Science and the recent advances of intensive computation, the industry is progressively shifting from a tangible prototype to a fully numerical and virtual prototype with the goal of reducing costs during the R&D phase. During the past few years, the emergence of 3D printers has enabled virtual prototyping methods to take into account, at an early stage, some degree of fabricability, especially regarding the shape of the manufactured object. Beyond the shape of an object, predicting the final appearance of a virtual prototype remains a challenge of high potential for many domains (e.g., furniture, textile, architecture). The challenge is mainly due to the fact that the final appearance of an object is dependent on its shape, the material(s) applied on it as well as the viewing and lighting conditions. As shown in Figure 13, solving the inverse problem that goes from Pictorial Design [A] to the Operational Design [D], where a specialist controls the fabrication process, is very hard and ill-posed.

Scientific Objectives.

The VIDA project aims at removing the several scientific locks by establishing a framework for direct and inverse design of material appearance for objects of complex shape. Since the manufacturing processes are always changing and evolving, our goal is to establish a framework that is not tied to a fabrication stage. To provide a rich variety of possible appearances, we will target multi-layered materials. We will ensure that every step of our framework is validated by either predictive simulation and/or measurements of the appearance. To illustrate the fabricability of our results, material samples as well as object samples will be fabricated locally or out-sourced to Ecole des Mines de Saint-Etienne (http://www.mines-stetienne.fr/en/EMSE) or http://www.saint-gobain-recherche.frSaint-Gobain Recherche and their appearance will also be validated with specific devices developed at the https://www.institutoptique.fr/enInstitut d'Optique-http://www.lp2n.frLP2N.

|

“Young Researcher” RichShape (2014-2018)

MANAO

Leader G. Guennebaud

This project aims at the development of novel representations for the efficient rendering and manipulation of highly detailed shapes in a multi-resolution context.

ISAR (2014-2018)

POTIOC, MANAO, LIG-CNRS-UJF, Diotasoft

Leader M. Hachet (POTIOC)

The ISAR project focuses on the design, implementation and evaluation of new interaction paradigms for spatial augmented reality, and to systematically explore the design space.

MATERIALS (2015-2019)

MAVERICK, LP2N-CNRS (MANAO), Musée d'Ethnographie de Bordeaux, OCÉ-Print

Leader N. Holzschuch (MAVERICK)

Local Leader R. Pacanowski (LP2N-CNRS)

Museums are operating under conflicting constraints: they have to preserve the artifacts they are storing, while making them available to the public and to researchers. Cultural artifacts are so fragile that simply exposing them to light degrades them. 3D scanning, combined with virtual reality and 3D printing has been used for the preservation and study of sculptures. The approach is limited: it acquires the geometry and the color, but not complex material properties. Current 3D printers are also limited in the range of colors they can reproduce. Our goal in this project is to address the entire chain of material acquisition and restitution. Our idea is to scan complex cultural artifacts, such as silk cloths, capturing all the geometry of their materials at the microscopic level, then reproduce them for study by public and researchers. Reproduction can be either done through 2.5D printing or virtual reality displays.

FOLD-Dyn (2017-2021)

IRIT, IMAGINE, MANAO, TeamTo, Mercenaries

Leader L. Barthe (IRIT)

Local Leader G. Guennebaud (Inria)

The FOLD-Dyn project proposes the study of new theoretical approaches for the effective generation of virtual characters deformations, when they are animated. These deformations are two-folds: character skin deformations (skinning) and garment simulations. We propose to explore the possibilities offered by a novel theoretical way of addressing character deformations: the implicit skinning. This method jointly uses meshes and volumetric scalar functions. By improving the theoretical properties of scalar functions, the study of their joint use with meshes, and the introduction of a new approach and its formalism - called multi-layer 3D scalar functions - we aim at finding effective solutions allowing production studios to easily integrate in their pipeline plausible character deformations together with garment simulations.

Competitivity Clusters

LabEx CPU

IMB (UPR 5251), LABRI (UMR 5800), Inria (CENTRE BORDEAUX SUD-OUEST), I2M (NEW UMR FROM 2011), IMS (UMR 5218), CEA/DAM

Some members of MANAO participate in the local initiative CPU. As it includes many thematics, from fluid mechanics computation to structure safety but also management of timetable, safety of networks and protocols, management of energy consumption, etc., numerical technology can impact a whole industrial sector. In order to address problems in the domain of certification or qualification, we want to develop numerical sciences at such a level that it can be used as a certification tool.