Section: Software

Hardware

Poppy Platform

Participant : Matthieu Lapeyre [correspondant] .

Main goals :

No current platform (Nao [86] , Darwin Op [87] , Nimbro Op [117] , HRP-2, ...) does offer both a adapted morphology in the sense of allowing physical interaction (safe, compliant, playful) and optimized for walking. So to explore these challenges we have decided to build a new bio-inspired humanoid robotic platform, called Poppy, which provides some of the software and hardware features needed to explore both social interaction and biped locomotion for personal robot. It presents the following main features to make it an interesting platform to study how the combination of morphology and social interaction can help the learning:

Design inspired from the study of the anatomy of the human body and its bio-mechanic

Dynamic and reactive: we try to keep the weight of the robot as low as possible (geometry of the pieces and smaller motors)

Social interaction: screen for communication and permits physical interaction thanks to compliance

Study of the morphology of the leg to improve the biped walking

Practical platform: low cost, ease of use and easy to reproduce

Overview :

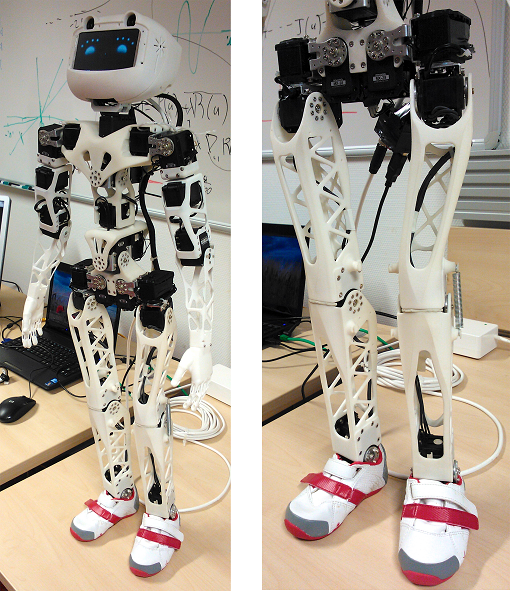

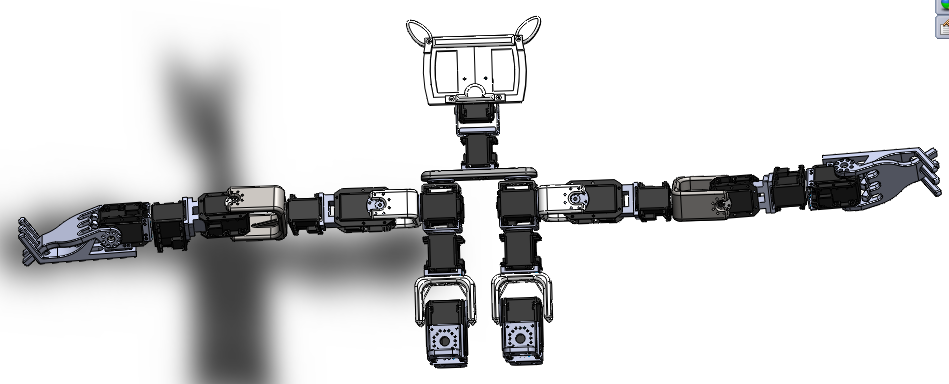

Poppy platform (Figure 11 ) is a humanoid, it is 84cm tall for 3 kg. It has a large sensor motors space including 25 dynamical motors (MX-28 and AX-12), force sensors under its feet and some extra sensors in the head: 2 HD-wide angle-cameras, stereo-micros and an inertial central unit (IMU 9DoF) plus a large LCD Screen (4 inch) for visual communication (e.g. emotions, instructions or debug). The mechanical parts were designed and optimized to be as light as possible while maintaining the necessary strength. For this, the choice of a lattice beam structure manufactured with 3Dprinting polyamide was used.

The poppy morphology is designed based on the actual human body. We have deeply studied the biomechanics of the human body and have extracted some interesting features for humanoid robotics. This inspiration is expressed in the whole structure (e.g. the limb proportions) and in particular in the trunk and legs.

Poppy uses the bio-inspired trunk system introduced by Acroban [98] . These five motors allow it to reproduce the main changes brought by the human spine. This feature allows the integration of more natural and fluid motion while improving the user experience during physical interactions. In addition, the spine plays a fundamental role in bipedal walking and postural balance by actively participating in the balancing of the robot.

The legs were designed to increase the stability and agility of the robot during the biped walking by combining bio-inspired, semi-passive, lightweight and mechanical-computation features. We will now describe two examples of this approach:

The architecture of the hips and thighs of Poppy uses biomechanical principles existing in humans. The human femur is actually slightly bent at an angle of about 6 degrees. In addition, the implantation of the femoral head in the hip is on the side. This results in a reduction of the lateral hip movement needed to move the center of gravity from one foot to another and a decrease in the lateral falling speed. In the case of Poppy, the inclination of its thighs by an angle of 6 degrees causes a gain of performance of more than 30% for the two above mentioned points.

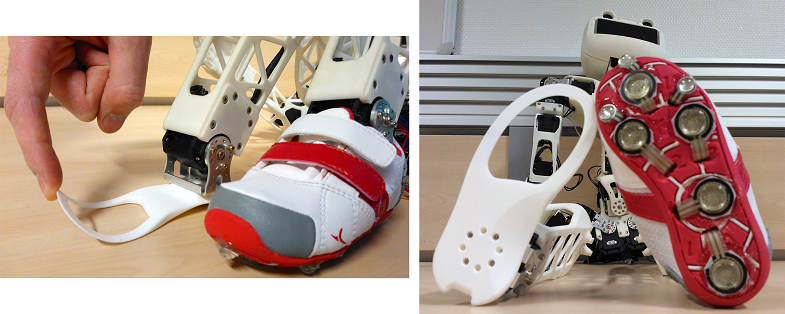

Another example is Poppy's feet. Poppy has the particularity of having small feet compared to standard humanoids. It has humanly proportioned feet (ie about 15% of its total size).It is also equipped with compliant toes joints (see Figure 12 .a). We believe that this feet involve two keys features to obtain a human-like and efficient walking gait. However, that raises problems regarding balance because the support polygon is reduced. We decided to add pressure sensors under each foot in order to get accurate feedback of the current state of the robot (see Figure 12 .b).

|

Future works :

In our work, we explore the combination of both a bio-inspired body and bio-inspired learning algorithms. We are currently working on experiments involving Poppy to perform skill learning. First we would like to succeed in achieving an effective postural balance using the articulated spine, the feet pressure sensors and the IMU. Then, we would like to perform experiments on the learning of biped walking using algorithms such as the ones described in [95] or [83] . We are expecting to clearly reduce the learning time needed and increase the quality of the learned tasks thanks to the bio-inspired morphology of Poppy.

We are also interested in social interactions with non-expert users. We would like to conduct user study to evaluate how playful physical interactions and emotions could improve learning in robotics. We think that the poppy platform could be very suitable for such studies.

Ergo-Robots/FLOWERS Fields: Towards Large-Scale Robot Learning Experiments in the Real World

Participants : Jerome Bechu, Fabien Benureau, Haylee Fogg, Paul Fudal, Hugo Gimbert, Matthieu Lapeyre, Olivier Ly, Olivier Mangin, Pierre Rouanet, Pierre-Yves Oudeyer.

In the context of its participation to the exhibition “Mathematics: A Beautiful Elsewhere” at Fondation Cartier pour l'Art Contemporain in Paris, starting from 19th October 2011 and to be held until 18th March 2012, the team, in collaboration with Labri/Univ. Bordeaux I, has elaborated and experimented a robotic experimental set-up called “Ergo-Robots/FLOWERS Fields” 13 . This set-up is not only a way to share our scientific investigations with the general public, but attacks a very important technological challenge impacting the science of developmental robotics: How to design a robot learning experiment that can run continuously and autonomously for several months? Indeed, developmental robotics takes life-long learning and development as one of its central objective and object of study, and thus shall require experimental setups that allow robots to run, learn and develop for extended periods of time. Yet, in practice, this has not been possible so far due to the unavailability of platforms adapted at the same time to learning, exploration, easy and versatile reconfiguration, and extended time of experimentation. Most experiments so far in the field have a duration ranging from a few minutes to a few hours. This is an important obstacle for the progress of developmental robotics, which would need experimental set-ups capable of running for several months. This is exactly the challenge explored by the Ergo-Robots installation, which we have approached by using new generations of affordable yet sophisticated and powerful off-the-shelf servomotors (RX Series from Robotis) combined with an adequately designed software and hardware architecture, as well as processes for streamlined maintenance. The experiment is now running for five months, six days a week, in a public exhibition which has strong constraints over periods of functioning and no continual presence of dedicated technicians/engineers on site. The experiment involved five robots, each with 6 degrees of freedoms, which are endowed with curiosity-driven learning mechanisms allowing them to explore and learn how to manipulate physical objects around them as well as to discover and explore vocal interactions with humans/the visitors. The robots are also playing language games allowing them to invent their own linguistic conventions. A battery of measures has been set up in order to study the evolution of the platform, with the aim of using the results (to be described in an article) as a reference for building future robot learning experiments on extended periods of time, both within the team and in the developmental robotics community. The system has been running during 5 months, 8 hours a day, with no major problems. During the two first months, the platform worked during 390h21mn, and was only stopped during 24h59mn (6 percent of time). After retuning the system based on what we learnt in the two first months, this performance was increased in the three last months: the platform worked for 618h23mn and was only stopped during 17h56mn (2.9 percent of time).

More information available at: http://flowers.inria.fr/ergo-robots.php and http://fondation.cartier.com/ .

|

The Ergo-Robots Hardware Platform

Participants : Jerome Bechu [correspondant] , Fabien Benureau, Haylee Fogg, Hugo Gimbert, Matthieu Lapeyre, Olivier Ly, Olivier Mangin, Pierre-Yves Oudeyer, Pierre Rouanet.

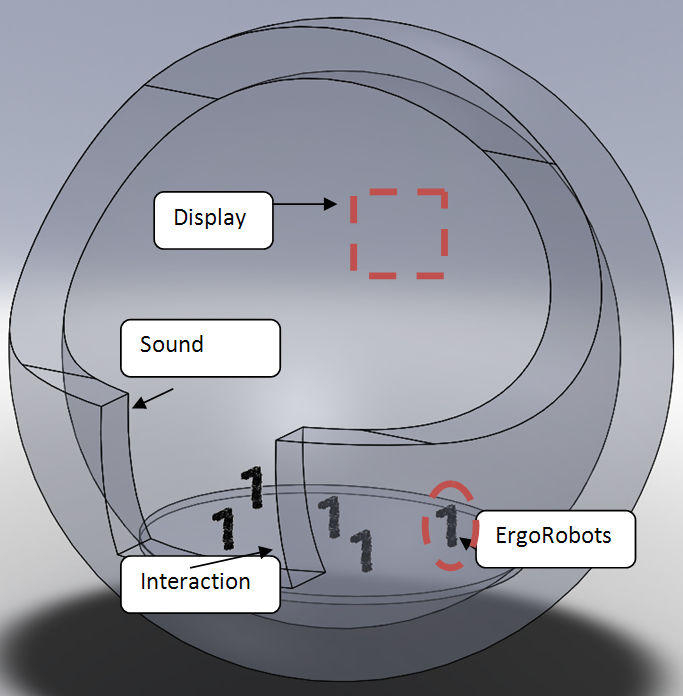

ErgoRobots 13 is a hardware platform for showcasing a number of curiosity and learning behaviours for the public to interact with. It was designed by the Flowers team in collaboration with Labri/Univ. Bordeaux I. The platform can also have future uses inside the lab for experiments that require more than one robot to complete. Although this system is entirely new this year, a very different previous version existed with the name FLOWERSField. It consists of five ErgoRobots, a control system, an interaction system, a display system, a sound system and a light system. There is an external system which monitors the ErgoRobots which contains a control system, a power system, a surveillance system and a metric capture system. The system has been running during 5 months, 8 hours a day, with no major problems. During the two first months, the platform worked during 390h21mn, and was only stopped during 24h59mn (6 percent of time). After retuning the system based on what we learnt in the two first months, this performance was increased in the three last months: the platform worked for 618h23mn and was only stopped during 17h56mn (2.9 percent of time).

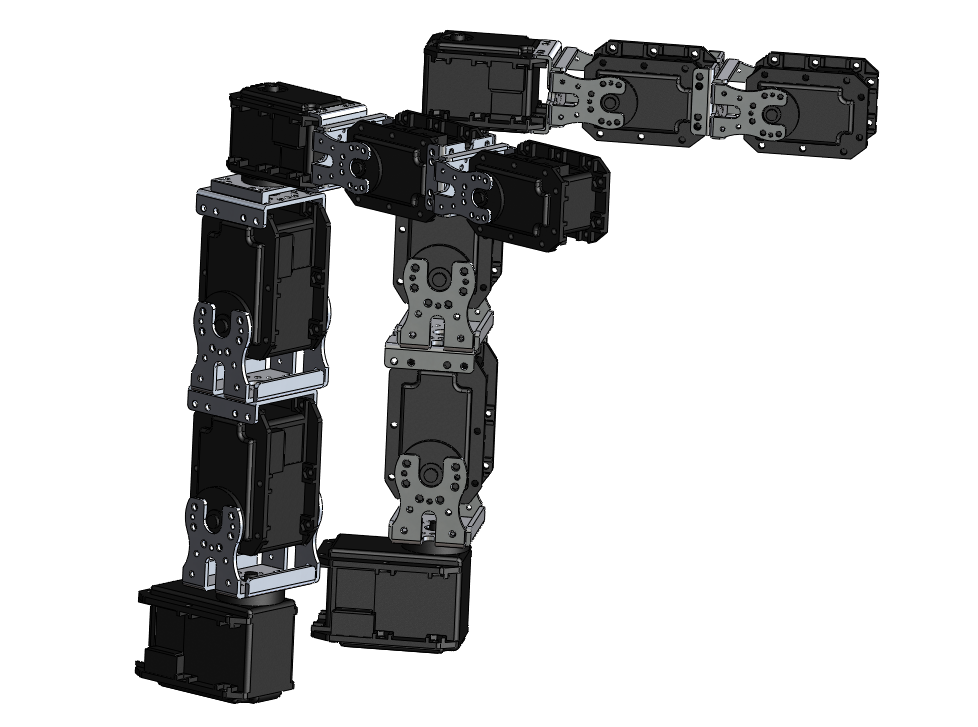

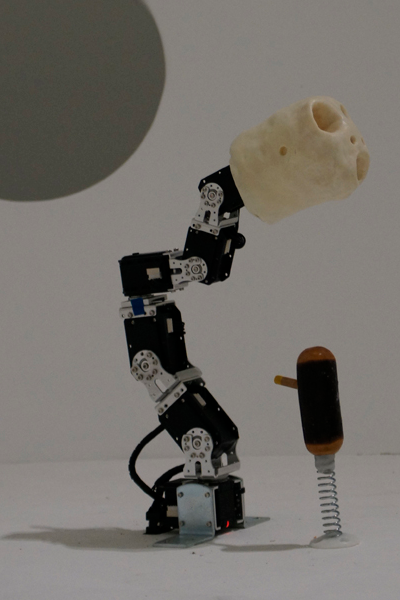

The Ergo-Robot system: The robots themselves are each composed of six motors (see figure). Currently, the heads of the robots have been created in wax by David Lynch and the entire system is displayed at Fondation Cartier inside a large egg shaped orb as shown in the following diagram. The control system module contains both an MMNET1002 control board with an UART-RS485 breakout board which communicates with a ubuntu Linux PC via an ethernet cable. The mment board communicates with the motors, but all other ErgoRobot systems communicate with the PC directly. The sound system is currently externally provided and communicates with the PC. The light system is a series of two or three BlinkM RGB leds placed inside each ErgoRobot head that are controlled through two LinkM USB devices directly with the computer. A kinect placed in front of the system operates as the means for the public to interact with the platform and communicates directly through USB to the PC. The display system is currently an externally provided projector that projects visualisations of the field's current state behind the ErgoRobots.

The external system: This system allows anyone that is monitoring the system to externally control the ErgoRobots system. The PC with which the software control takes place is a Ubuntu Linux system which communicates with the ErgoRobot control system via an ethernet cable. The ErgoRobot harware system can be managed by an external power system which includes a 15.5V bench top power supply for the ErgoRobot motors, an external 12V plug in adapter for the mment board, an external 5V plug in adapter for the LED lights which are all controlled via an emergency stop button. The maintenance system can be located out of direct view of the ErgoRobot field as it has a surveillance system: a kinect that can display the current state of the field. More surveillance is conducted through a metric capture system that communicates with the ErgoRobots to obtain various state values of the ErgoRobots through the motor sensors and other data. This surveillance is not entirely in place as of 2011 and will be implemented in early 2012.

Stem Platform for Affordances

Participant : Fabien Benureau [correspondant] .

The Stem Platform for Affordances (figure 15 is a hardware platform that is intended for use in the lab for experiments. It features a 6 DOFs arm robot identical to the other robot stems present in the lab, and a physical platform intended for the interaction with objects. Our affordance experiments involves a lot of trials; there was the need for a platform that could reset itself after the robot interacted, as it is an assumption underlying our current algorithms. The stem platform provides exactly that, with the object position and orientation being reseted by the platform autonomously and in less than 10 seconds. This provides the potential to do more than 2000 independent interactions with an object over the course of 12 hours.

The platform also provides sensory capabilities, being able to track the position and orientation of the object at all time. On the hardware side, a camera is used. We investigated both a standard PSEye, that provides a high framerate (120Hz) with noise, and a high quality, firewire camera with professional optics, providing higher resolution, low noise at the expense of a low framerate (15Hz). The latter was kindly provided by the Potioc team. On the software side, computing the position is done by the open-source augmented reality library ARToolkitPlus. On the objects themselves, AR tags are placed.

The platform is supported by a simulation that reproduce the setup in V-Rep. In order to be able to use the same algorithms for both the hardware and the simulation, a low-level interface was written for Pypot and V-Rep, using the work done by Paul Fudal on V-Rep Bridge.

The complete platform took roughly 3 weeks to make, with 3 additional weeks for the software. The team recently acquired material that would make possible to build a similar platform faster and in a more robust material (wood is used in the first platform). This platform, backed up by its simulation, will allow us to perform planned experiments in a reliable and statistically significant manner.

Humanoid Robot Torso

Participant : Haylee Fogg [correspondant] .

The Humanoid Robot Torso is a hardware platform that is intended for use in the lab for either experiments or demonstrations 16 . It consists of a humanoid robot that contains just a torso, arms with shoulders and grippers, and head. It is entirely new this year, as a new design has been made, and a skeleton built with 3D printing technologies. The arms with the claws contain seven degrees of freedom (including 'grip'). The head consists of a smartphone for the face and an associated camera for the 'eyes' with the ability to move in two degrees (pitch and roll). The hardware is both robotis Dynamixel RX-28 and R-64 motors attached together with standard robotis frames and 3D printed limbs. A wiki has been built, documenting both the hardware and software platform.

NoFish platform

Participants : Mai Nguyen [correspondant] , Paul Fudal [correspondant] , Jérôme Béchu.

The NoFish platform is a hardware platform that is intended for use in the lab for experiments. It consists of an ErgoRobot with an attached fishing rod. The robot is fixed on a table and has in front of him a delimited area where to throw the fishing cap. This area is covered by a camera in order to track the fishing cap and to give its coordinates. The robot is managed by a software written using the Urbi framework. This program controls the robot using pre-programmed moves and also gives a way to uses the robot joint by joint. A second software written in C++ using OpenCV framework tracks the position of the fishing cap and sends the coordinates to the Urbi software controlling the robot. Finally, at the upper layer of the software architecture, MatLab is used to implement different learning algorithms. All MatLab code is able to receive informations from the Urbi part of the software (fishing cap coordinates, joints informations, etc) and also to send order to the robot (position joint by joint, preprogrammed moves, etc). To finish, and because the platform can run a learning algorithms during a long time, an electric plug managed by the Urbi part of the software is added to the platform to shutdown the power if the robot is blocked or does not respond anymore.