Section: Research Program

Research Program

The research will first focus on the extension and implementation of current techniques as developed in I4S and IFSTTAR. Before doing any temperature rejection on large scale structures as planned, we need to develop good and accurate models of thermal fields. We also need to develop robust and efficient versions of our algorithms, mainly the subspace algorithms before envisioning linking them with physical models. Briefly, we need to mature our statistical toolset as well as our physical modeling before mixing them together later on.

Vibration analysis and monitoring

Direct vibration modeling under temperature changes

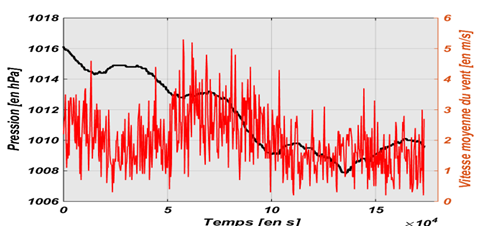

This task builds upon what has been achieved in the CONSTRUCTIF project, where a simple formulation of the temperature effect has been exhibited, based on relatively simple assumptions. The next step is to generalize this modeling to a realistic large structure under complex thermal changes. Practically, temperature and resulting structural prestress and pre strains of thermal origin are not uniform and civil structures are complex. This leads to a fully 3D temperature field, not just a single value. Inertia effects also forbid a trivial prediction of the temperature based on current sensor outputs while ignoring past data. On the other side, the temperature is seen as a nuisance. That implies that any damage detection procedure has first to correct the temperature effect prior to any detection.

Modeling vibrations of structures under thermal prestress does and will play an important role in the static correction of kinematic measurements, in health monitoring methods based on vibration analysis as well as in durability and in the active or semi-active control of civil structures that by nature are operated under changing environmental conditions. As a matter of fact, using temperature and dynamic models the project aims at correcting the current vibration state from induced temperature effects, such that damage detection algorithms rely on a comparison of this thermally corrected current vibration state with a reference state computed or measured at a reference temperature. This approach is expected to cure damage detection algorithms from the environmental variations.

I4S will explore various ways of implementing this concept, notably within the FUI SIPRIS project.

Damage localization algorithms (in the case of localized damages such as cracks)

During the CONSTRUCTIF project, both feasibility and efficiency of some damage detection and localization algorithms were proved. Those methods are based on the tight coupling of statistical algorithms with finite element models. It has been shown that effective localization of some damaged elements was possible, and this was validated on a numerical simulated bridge deck model. Still, this approach has to be validated on real structures.

On the other side, new localization algorithms are currently investigated such as the one developed conjointly with University of Boston and tested within the framework of FP7 ISMS project. These algorithms will be implemented and tested on the PEGASE platform as well as all our toolset.

When possible, link with temperature rejection will be done along the lines of what has been achieved in the CONSTRUCTIF project.

Uncertainty quantification for system identification algorithms

Some emphasis will be put on expressing confidence intervals for system identification. It is a primary goal to take into account the uncertainty within the identification procedure, using either identification algorithms derivations or damage detection principles. Such algorithms are critical for both civil and aeronautical structures monitoring. It has been shown that confidence intervals for estimation parameters can theoretically be related to the damage detection techniques and should be computed as a function of the Fisher information matrix associated to the damage detection test. Based on those assumptions, it should be possible to obtain confidence intervals for a large class of estimates, from damping to finite elements models. Uncertainty considerations are also deeply investigated in collaboration with Dassault Aviation in Mellinger PhD thesis or with Northeastern University, Boston, within Gallegos PhD thesis.

Reflectometry-based methods for civil engineering structure health monitoring

The inverse scattering method we developed is efficient for the diagnosis of all soft faults affecting the characteristic impedance, the major parameter of a cable. In some particular applications, however, faults would rather affect the series resistance (ohmic loss) or shunt conductance (leakage loss) than the characteristic impedance. The first method we developed for the diagnosis of such losses had some numerical stability problems. The new method is much more reliable and efficient. It is also important to develop efficient solutions for long cables, up to a few kilometers.

For wired networks, the methods we already developed cover either the case of simple networks with a single node measurement or the case of complex networks with complete node measurements. Further developments are still necessary for intermediate situations.

In terms of applications, the use of electric cables as sensors for the monitoring of various structures is still at its beginning. We believe that this new technology has a strong potential in different fields, notably in civil engineering and in materials engineering.

Non Destructive testing of CFRP bonded on concrete through active thermography

Strengthening or retrofitting of reinforced concrete structures by externally bonded fibre-reinforced polymer (FRP) systems is now a commonly accepted and widespread technique. However, the use of bonding techniques always implies following rigorous installation procedures. The number of carbon fibre-reinforced polymer (CFRP) sheets and the glue layer thickness are designed by civil engineers to address strengthening objectives. Moreover, professional crews have to be trained accordingly in order to ensure the durability and long-term performance of the FRP reinforcements. Conformity checking through an ‘in situ’ verification of the bonded FRP systems is then highly desirable. The quality control programme should involve a set of adequate inspections and tests. Visual inspection and acoustic sounding (hammer tap) are commonly used to detect delaminations (disbonds). Nevertheless, these techniques are unable to provide sufficient information about the depth (in case of multilayered composite) and width of the disbonded areas. They are also incapable of evaluating the degree of adhesion between the FRP and the substrate (partial delamination, damage of the resin and poor mechanical properties of the resin). Consequently, rapid and efficient inspection methods are required. Among the non-destructive (NDT) methods currently under study, active infrared thermography is investigated due to its ability to be used in the field. In such context and to reach the aim of having an in situ efficient NDT method, we carried out experiments and subsequent data analysis using thermal excitation. Image processing, inverse thermal modelling and 3D numerical simulations are used and then applied to experimental data obtained in laboratory conditions.

IRSHM: Multi-Sensing system for outdoor thermal monitoring

Ageing of transport infrastructures combined with traffic and climatic solicitations contribute to the reduction of their performances. To address and quantify the resilience of civil engineering structure, investigations on robust, fast and efficient methods are required. Among research works carried out at IFSTTAR, methods for long term monitoring face an increasing demand. Such works take benefits of this last decade technological progresses in ICT domain.

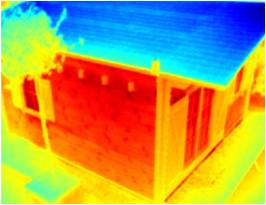

Thanks to IFSTTAR years of experience in large scale civil engineering experiment, I4S is able to perform very long term thermal monitoring of structures exposed to environmental condition, as the solar heat flux, natural convection or seasonal perturbation. Informations system are developed to asses the data acquisition and researchers work on the quantification of the data to detect flaws emergence on structure, those techniques are also used to diagnose thermal insulation of buildings or monitoring of guided transport infrastructures, Figure 4 left. Experiments are carried out on a real transport infrastructure open to traffic and buildings. The detection of the inner structure of the deck is achieved by image processing techniques (as FFT), principal component thermography (PCT), Figure 4 right, or characterization of the inner structure thanks to an original image processing approach.

|

For the next few years, I4S is actively implied in the SenseCity EQUIPEX (http://sense-city.ifsttar.fr/) where our informations systems are used to monitor a mini-city replica, Figure 5.

|

R5G: The 5th Generation Road

The road has to reinvent itself periodically in response to innovations, societal issues and rising user expectations. The 5th Generation Road (R5G) focuses firmly on the future and sets out to be automated, safe, sustainable and suited to travel needs. Several research teams are involved in work related to this flagship project for IFSTTAR, which is a stakeholder in the Forever Open Road. Through its partnership with the COSYS (IFSTTAR) department, I4S is fully implicated in the development of the 5th Generation Road.

Most of the innovations featured in R5G are now mature, for example communication and few solutions for energy exchange between the infrastructure, the vehicle and the network manager; recyclable materials with the potential for self-diagnosis and repair, a pavement surface that remains permanently optimal irrespective of climatic variations… Nevertheless, implementing them on an industrial scale at a reasonable cost still represents a real challenge. Consultation with the stakeholders (researchers, industry, road network owners and users) has already established the priorities for the creation of full-scale demonstrators. The next stages are to achieve synergy between the technologies tested by the demonstrators, to manage the interfaces and get society to adopt R5G.