Section: New Results

Modeling activities and forecasting energy consumption and production to promote the use of self-produced electricity from renewable sources

Participants : Alexandre Rio, Yoann Maurel [contact] .

This work began in 2017 and is carried out as part of a broader collaboration between EASE, the Diverse Team and OKWind, a company specialized in the production of renewable sources of energy. OKWind proposes to deploy self-production units directly where the consumption . It has developed expertise in vertical-axis wind turbines,photovoltaic trackers, heat pump and energy storage devices. An interesting aspect of renewable energies is that they can be produced locally, close to the consumers, thus considerably reducing infrastructures and distribution costs.The autonomy of sites with micro-generation capabilities is then greatly increased by self-consumption of locally produced energy.

Designing solutions in favor of self-consumption for small industries or city districts is challenging. It consists in designing an energy production system made of solar panels, wind turbines, batteries that fit the annual weather prediction and the industrial or human activity. This raises several issues. How to precisely assess the consumption and production of energy on a given site with changing conditions? How to adequately size energy sources and energy storage (wind turbine, solar panel and batteries)? What methods to use to optimize consumption and, whenever possible, act on installations and activities to reduce energy costs?

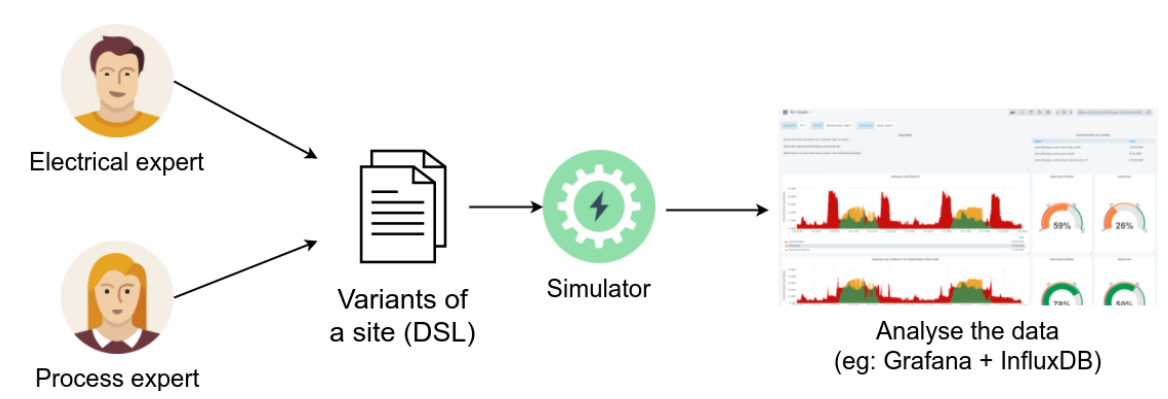

We aim to design an integrated tool-suite to assist the engineers in dimensioning an Energy Management System (EMS) for an isolated site to reduce the construction of new network infrastructure and reduce its dependence on the grid. We advocate that the MDE is a very good candidate to integrate the various technological and business knowledge on the renewable energy production and consumption forecasting techniques, the planning of processes, energy costs, grid, and batteries. The development of a DSL to describe the relationships between activities, their planning, and the production and environmental factors would make possible to simulate a given site at a given location, to make assumptions on sizing, and would be a basis to forecast energy consumption so as to provide recommendations for the organization of activities. Using a DSL and components that clearly separate the different concerns would avoid code redundancies and would facilitate the work of domain experts.

In 2018, we developed a prototype of the Energy Management System (EMS) and a complete DSL that enables experts to quickly integrate their knowledge and algorithms, and to provide a library of reusable components and algorithms. The DSL reflects the different aspects of site modeling: batteries, producers, grid, machines used, and activities performed. It provides the necessary information and constraints so that the EMS can propose an arrangement of activities that optimizes the consumption of renewable energy. The system can be improved by extending existing components or adding new ones. Some of these components are also able to play back historical data, which is a common use for sizing purposes. The prototype is made of 4500 lines of Java code, 1300 loc of Lua and 78k loc of generated files.

This prototype has been tested in production to model agricultural sites. The great interest of our tool is that it enables to simulate easily a very wide range of situations and thus allows to determine quickly the best options. If we compare with the company's past practices, engineers mainly used homemade excel sheets and R script: sharing information among experts was very difficult and detecting errors in site modeling was challenging. Building this domain specific language and its associated simulator saves lots of time and produces more precise results compared to the traditional manual approaches used before (see figure 3).

We are now conducting an experiment at several sites to see how adapting activities can improve production equipment profitability. This experience over a long period should provide us with relevant feedback on what can and cannot be requested from a site operator. This should allow us to use our tool not only to simulate upstream but also to make observations and recommendations on a weekly basis. We also want to improve the constraint systems to integrate the modeling of more resources (hot and cold water, number of employees, machine availability). Finally, we would like to explore how this model can be used as a basis for artificial intelligence algorithms to manage real-time operations.

This work has been published in the conference Models 2018 [11].