Section:

New Results

Curved slicing

Figure

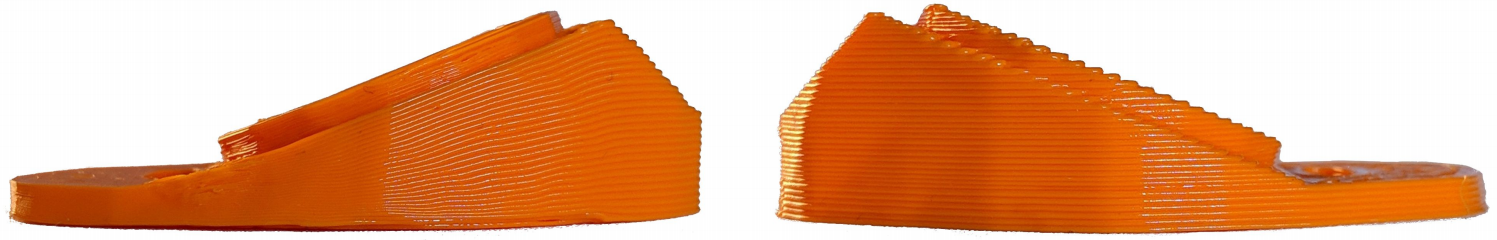

3. Sides views of curved slicing print (left) and adaptive slicing (right). Curved slicing eliminates all staircasing while closely following the input.

|

|

When printing 3D objects with Fused Filament Fabrication technology, the plastic is deposited by following a 2D path for producing the first layer.

Each following layer is printed with the same method on the top of the previous layers.

For technical reasons, it is convenient to use horizontal layers with constant height, but this generates aliasing errors that are especially visible (Figure 3, right) when the object's surface is close to horizontal.

The objective of this project is to reduce these artefacts by printing curved layers (Figure 3, left).

Printing curved layers is a challenging task because all technical aspects of printing have to be adapted to the curved case.

The key idea of our approach is to (virtually) deform the object in such a way that the surface that is close to horizontal becomes exactly horizontal,

then define all the printing instructions (tool path, slicing, pressure, etc.) in this deformed space with standard algorithms.

The final printing instructions are obtained by coming back to the original space.

In collaboration with MFX team, we have worked on the problem of finding the deformation by a global optimization method that tries to make horizontal large portions of the object's surface under constraints of layer thickness, tools collisions, object self-intersections, etc.

The results were published at SIGGRAPH this year [7].