Section: Application Domains

Effusion cooling of aeronautical combustion chambers walls

The industrial applications of our project is the cooling of the walls of the combustion chambers encountered in the helicopter engines, and more precisely, we wish to contribute to the improvement of effusion cooling.

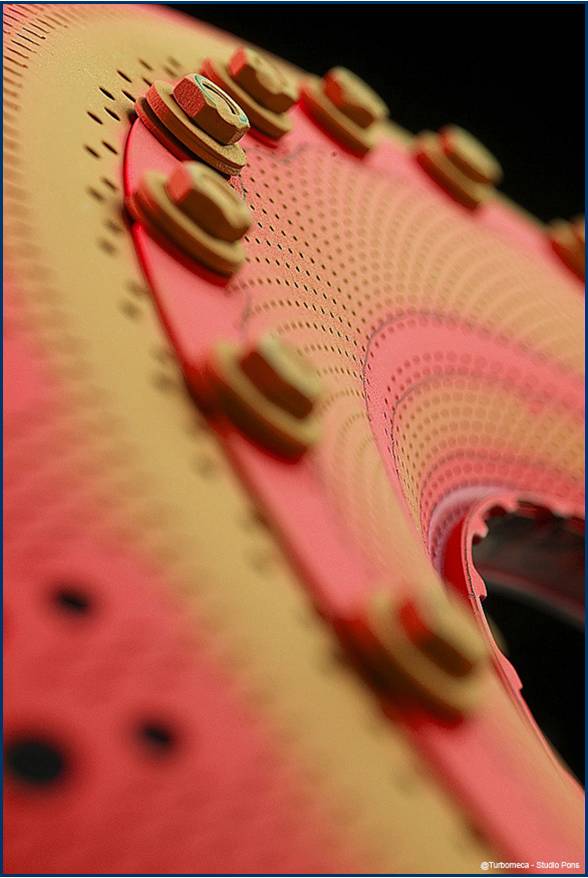

Effusion cooling is nowadays very widespread, especially in the aeronautical context. It consists in piercing holes on the wall of the combustion chamber. These holes induce cold jets that enter inside the combustion chamber. The goal of this jet is to form a film of air that will cool the walls of the chamber, see Figure 2 .

|

Effusion cooling in a combustion chamber takes at the wall where thousands of small holes allow cool air to enter inside the combustion chamber. This induces jets in crossflow in charge of cooling the walls, whatever the heat and the acoustic waves present inside the chamber. Nevertheless, this technique is not straightforward to put in practice: the size, design and position of the holes can have an important effect on the cooling efficiency. For a safe and efficient functioning of the combustion chamber, it is required that the cooling jets and the combustion effects be as much independent as possible. For example, this means that

The jets of cool air should not mix too much with the internal flow. Otherwise it will decrease the efficiency of the combustion.

The jets should be as much stable as possible when submitted to waves emitted in the combustion chamber, e.g. acoustic waves induced by combustion instabilities. Otherwise the jets may not cool enough the walls of the combustion chamber which can then undergoes severe damages.

The first point is what we aim at simulate in this project. As the model chosen is the fully compressible Navier Stokes system, there should not be any problem in the future for being able to simulate the effect of an acoustic forcing on the jet in crossflow.

Having a database of Direct Numerical Simulations is also fundamental for testing closure laws that are used in turbulence models encountered in RANS and LES models. With such models, it is possible for example to perform optimisation.

A last aspect, that will not be dealt with in this project, but that could be dealt with in the future, is the interaction between the flow and the wall. The aim is to understand the effect of coupling between the heat propagation in the wall and the flow near the wall. A careful study of this interaction can allow to determine the exchange coefficients, and so the efficiency of the cooling by the jet. Such determination may particularly useful to develop one or multidimensional models of wall-fluid interaction [19] .

From the application point of view, compressibility effects must be taken into account since the Mach number of the flow can reach values equal to , hence/or acoustic waves may be present inside the combustion chamber. This can raise a problem, because upwind numerical schemes are known to be less accurate in the low Mach limit.